Side by side with the industry – research with large-scale plants in full-scale

The leap from initial idea to evaluable application requires a professionally equipped large-scale scientific facility environment, particularly for manufacturing implementation. This is especially relevant for aeronautical applications with a TRL of four to six, but also to other applications, such as wind turbine rotor blades. Representing the processes involved in a simulative way is essential for the efficient implementation of research tasks and also offers the possibility of transferring acquired knowledge to different process and cycle rates.

Areas of competence

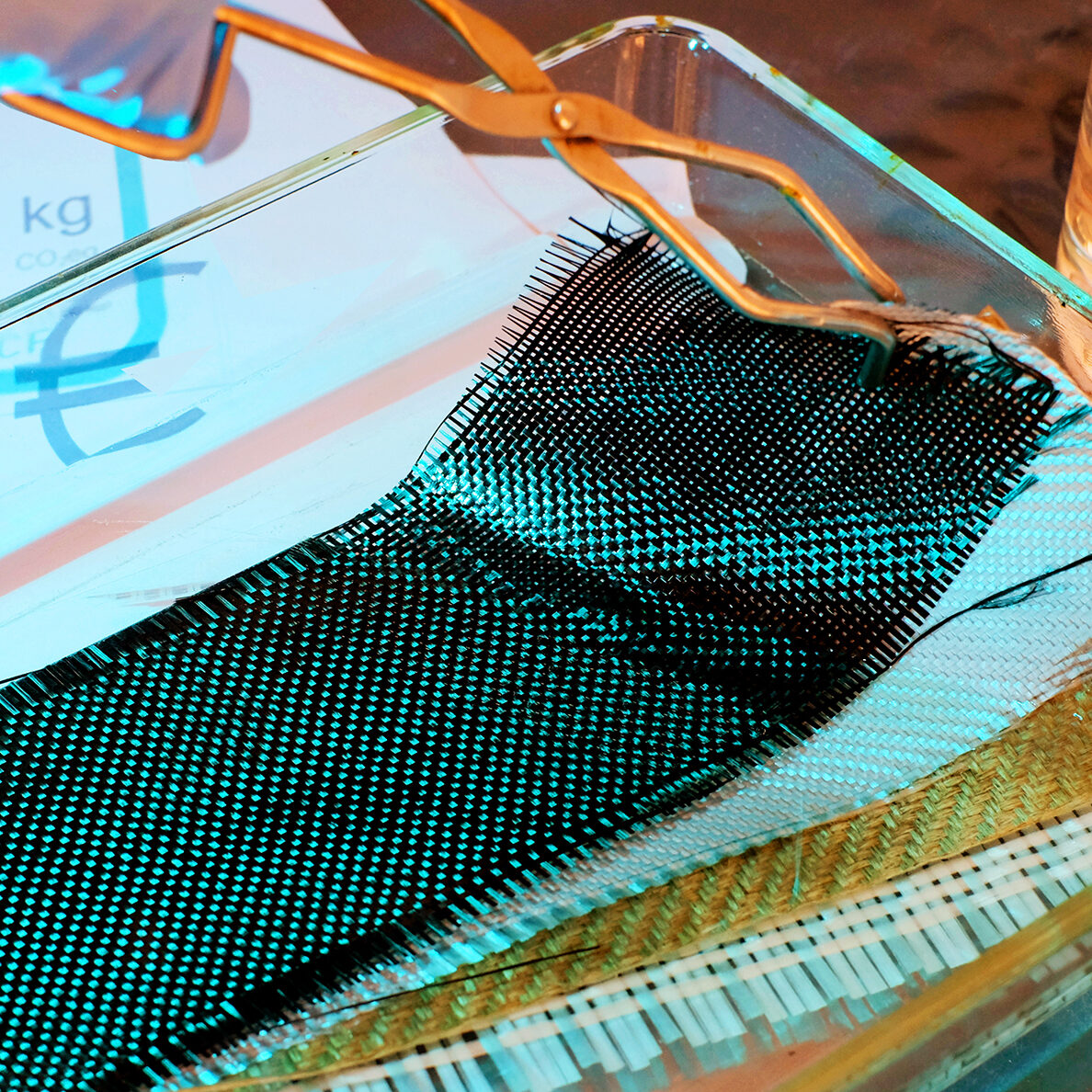

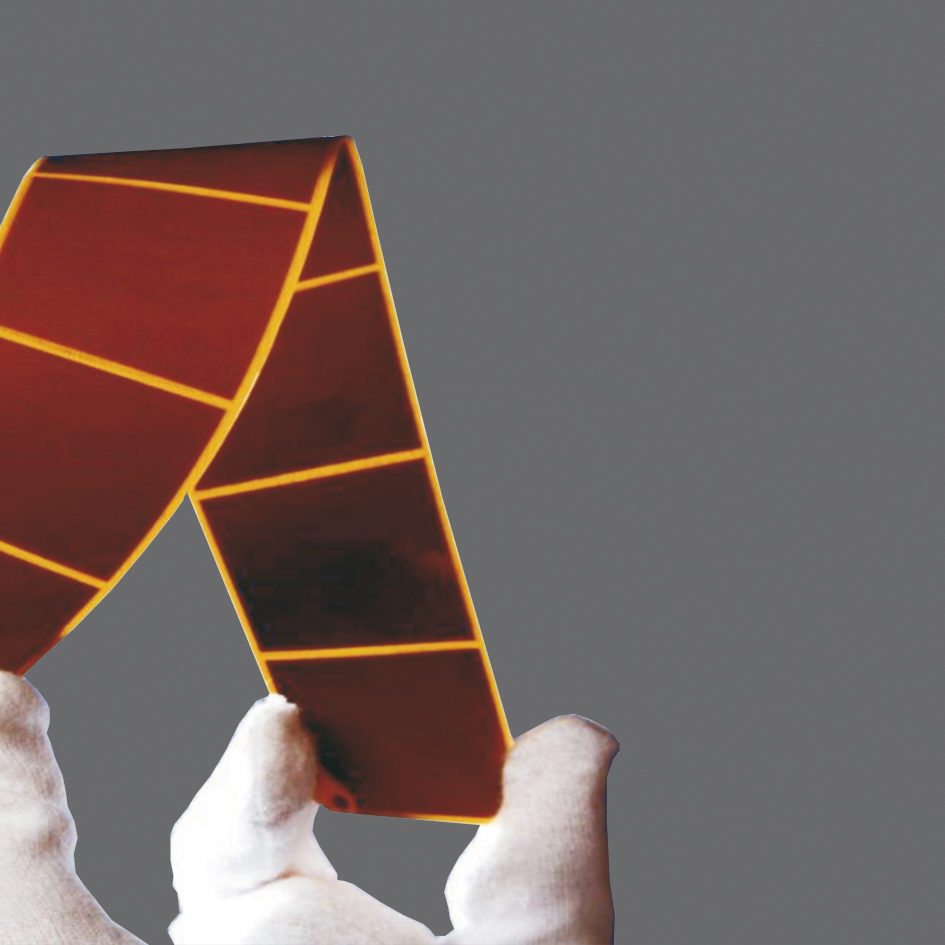

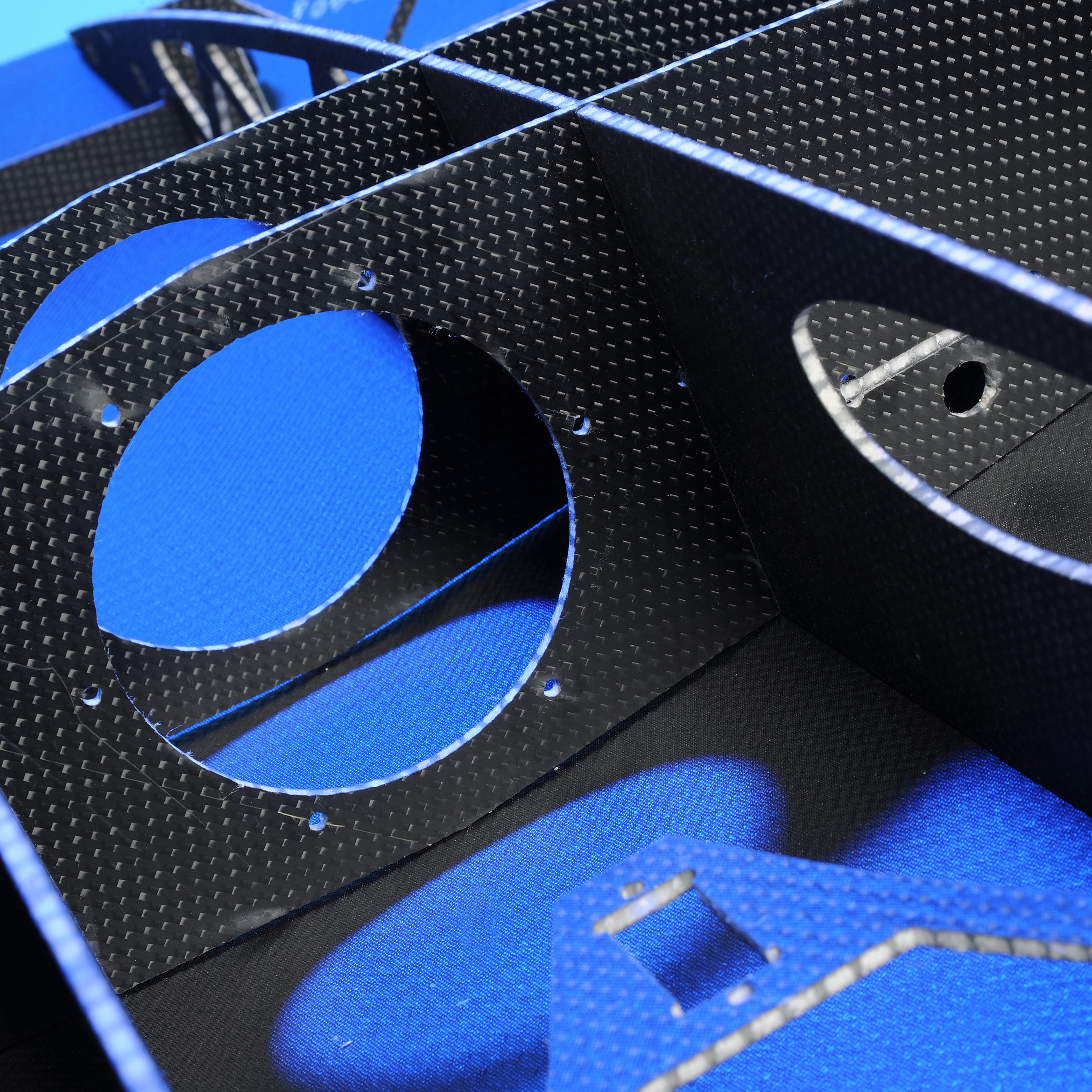

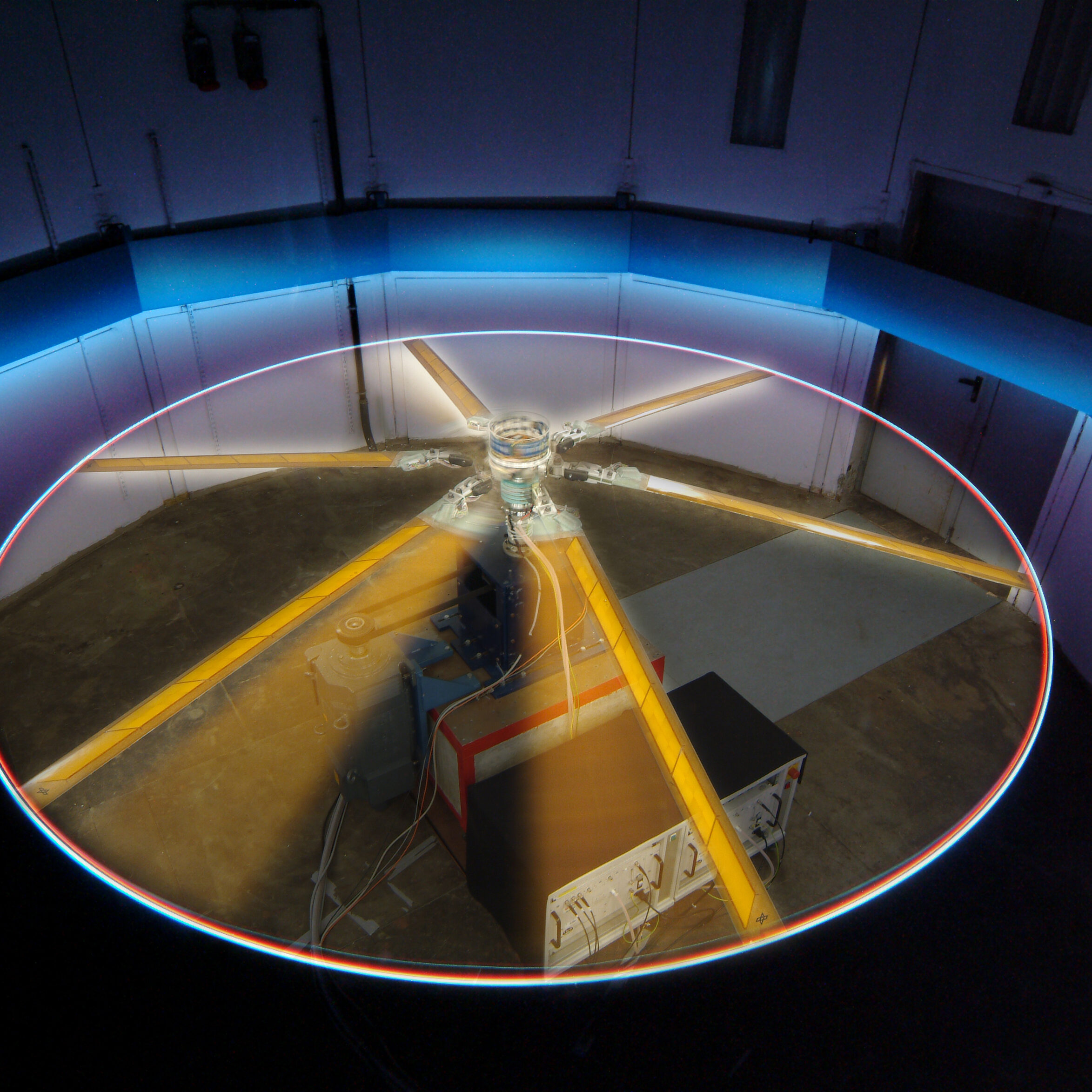

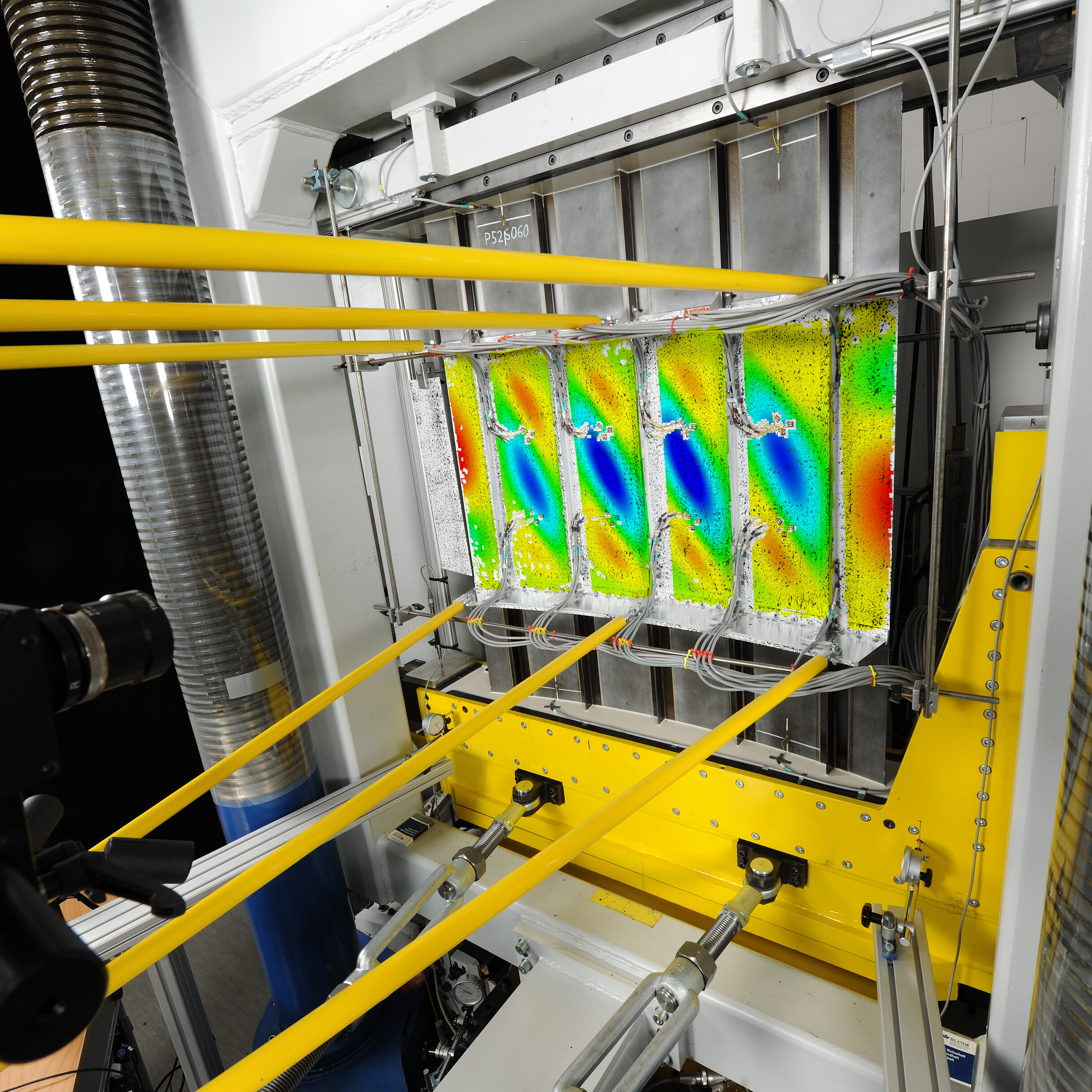

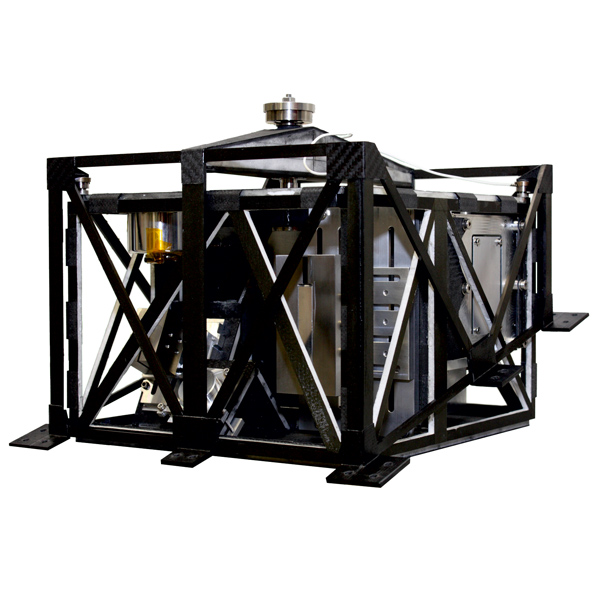

On the equipment side, the range of the Production Technologies Department covers manufacturing scenarios from press, RTM and autoclave technologies to fibre laying and filament winding technologies. All of the facilities are digitally interconnected and are equipped with the latest control and quality assurance technologies. Production costs as well as resource and energy efficiency are evaluated.

Overview of the large-scale facilities:

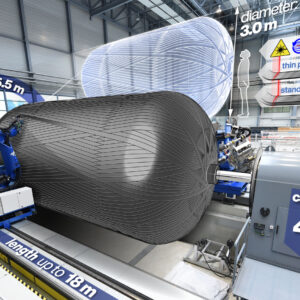

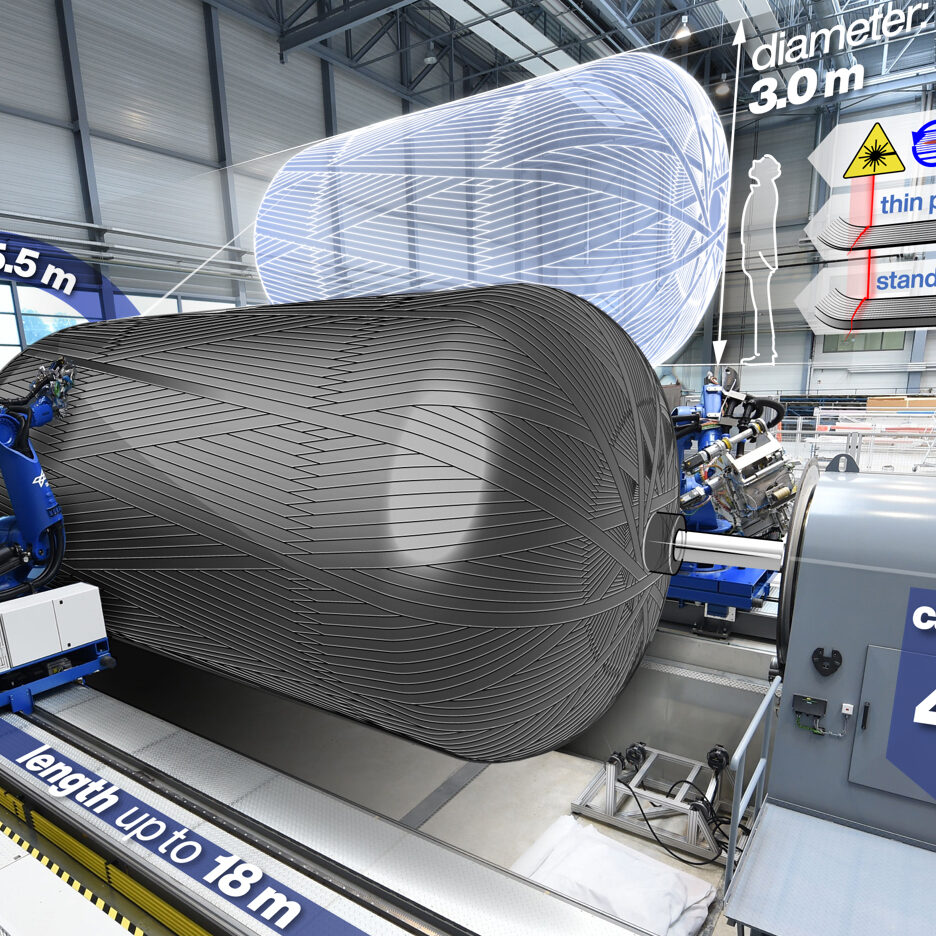

- GroFi®: Scenario-flexible research platform for multi-robotic fibre placement / tape laying and winding processes. Component sizes up to 18 metres by 5.5 metres.

- EVo: Research platform for fully automated textile preforming and RTM processes to realise large volumes in FRP component production. Component footprint up to 2.0 metres by 2.5 metres.

- BALU®: Research autoclave for effective heating methods, and simulation-supported and resource-efficient curing and consolidation processes. Loading dimensions up to 20 metres by 5.8 metres, pressure up to 10 bar and temperatures up to 420 degrees Celsius; sensor networks for quality-assurance monitoring of large structures.

- MACS®: Research autoclave with optional microwave heating and video surveillance. Loading dimensions up to 4.0 metres by 1.6 metres, pressures up to 10 bar and temperatures up to 200 degrees Celsius; 1.2 metres by 1.2 metres laboratory autoclave, pressure up to 10 bar and temperatures up to 400 degrees Celsius with several observation windows for testing sensor networks.

Range of services

- Application-oriented manufacturing processes and efficient heating methods

- Process understanding in automated FRP production

- Process and technology expertise for fibre laying processes, curing / consolidation processes and textile preforming and RTM processes

- Large-scale technology development and demonstration

- Realisation of innovative lightweight structures

- Sensor-guided processing and quality assurance for energy-efficient heating methods

- Energy management and carbon-dioxide footprint in the life cycle / balancing of resource efficiency

- Digitalisation / Industry 4.0, virtual manufacturing and evaluation models

- Approaches to automation and digitalisation

- Process simulation, digital equipment and component twins

- Sustainable manufacturing and assembly through digitalisation

- Methods and technologies for inline quality assurance

- Machine learning approaches (AI) in production technologies

- Digital process data management