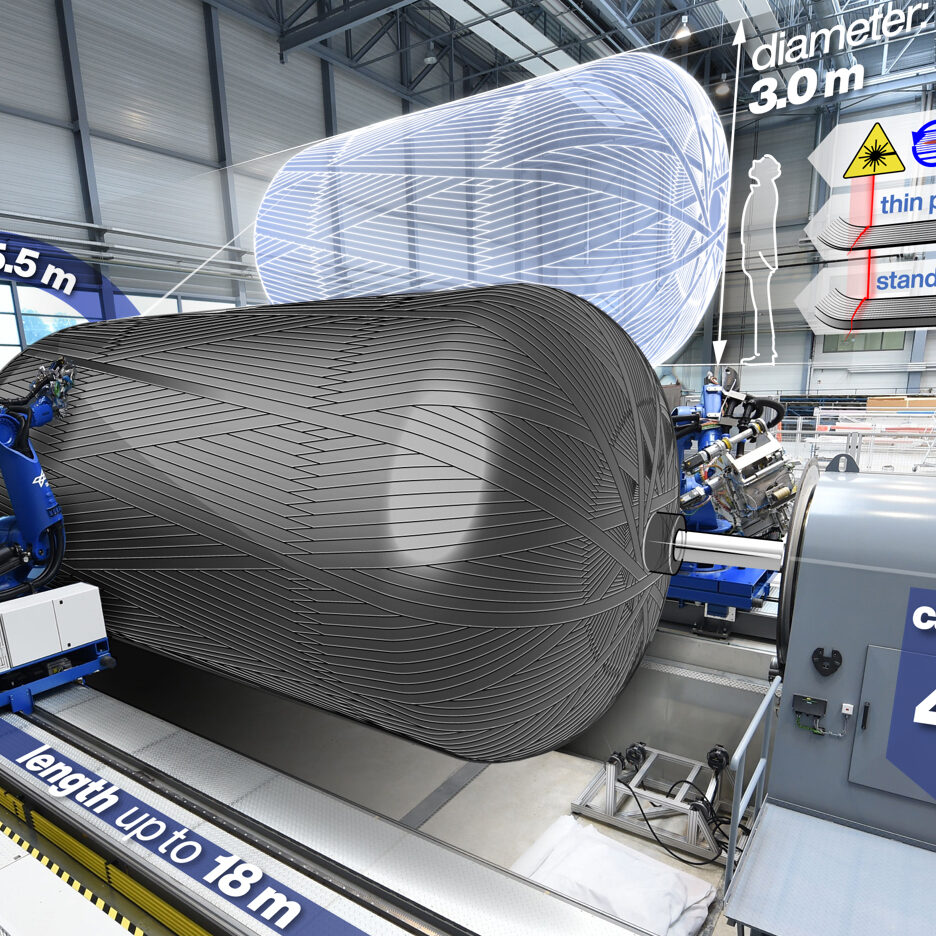

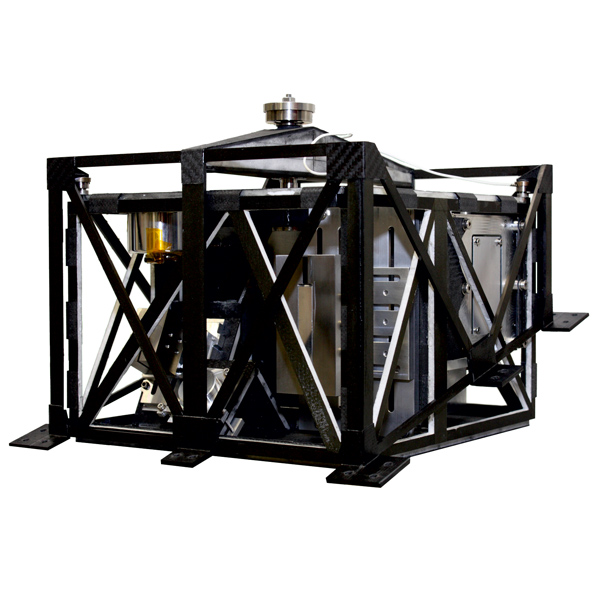

New materials with superior properties are the basis for innovative technologies. The department’s research focuses on integrating additional functionalities into the material in order to increase the competitiveness and the field of application of fibre composites. By developing high-performance lightweight materials, we are making a significant contribution to the sustainable mobility of tomorrow..

Competences

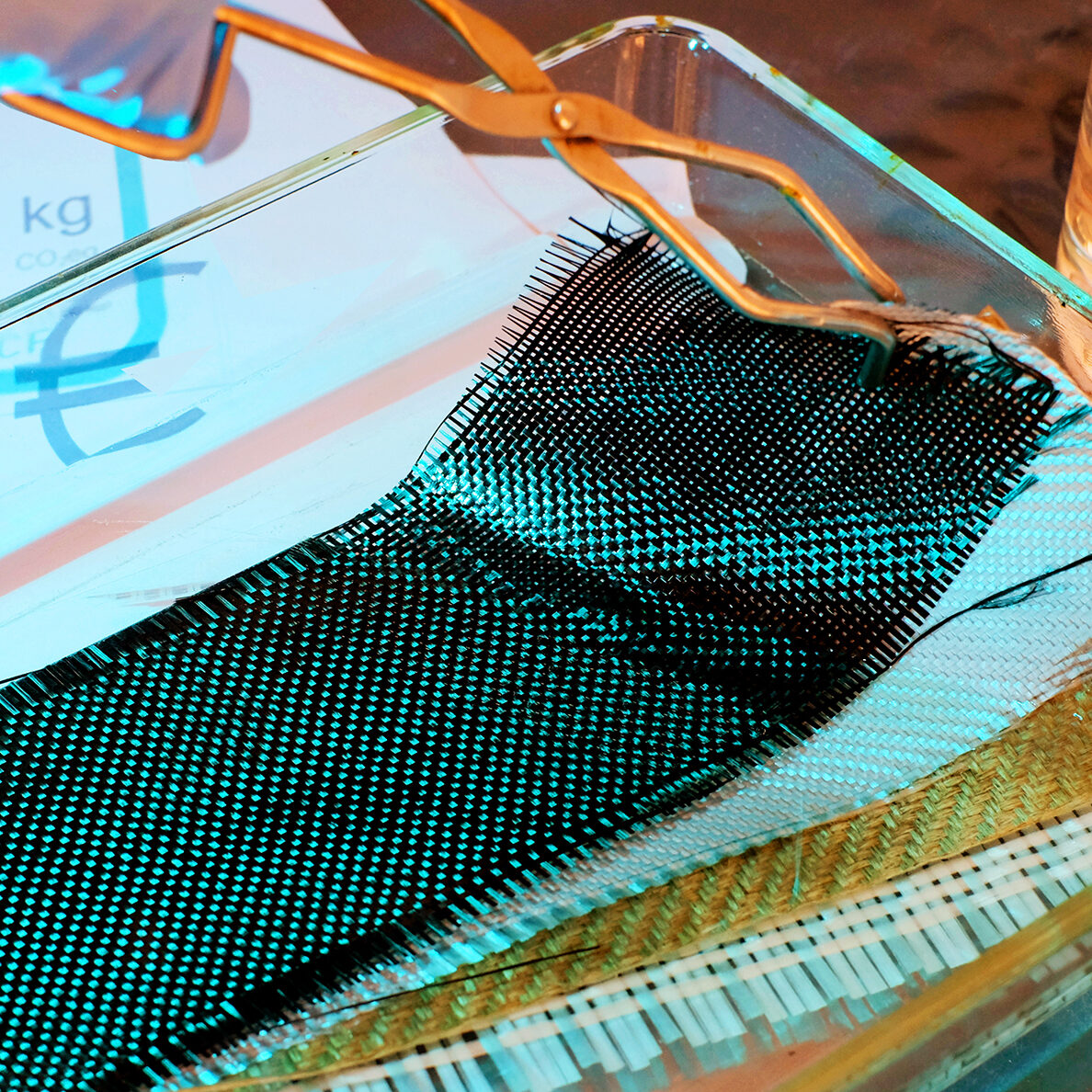

Future work will be directed towards specifically designing the properties and functionalities of multi-material systems across scales (nano – micro – macro) and adjusting them in the manufacturing process. To improve matrix-dominated properties, we use various dispersion processes for the production of nanocomposites and deal with the compounding and extrusion of thermoplastic materials for generative manufacturing processes. In addition to classical composites, we are also investigating the potential of natural fibres, recycled fibres and the inte-gration of smart materials with sensory and actuator functions.

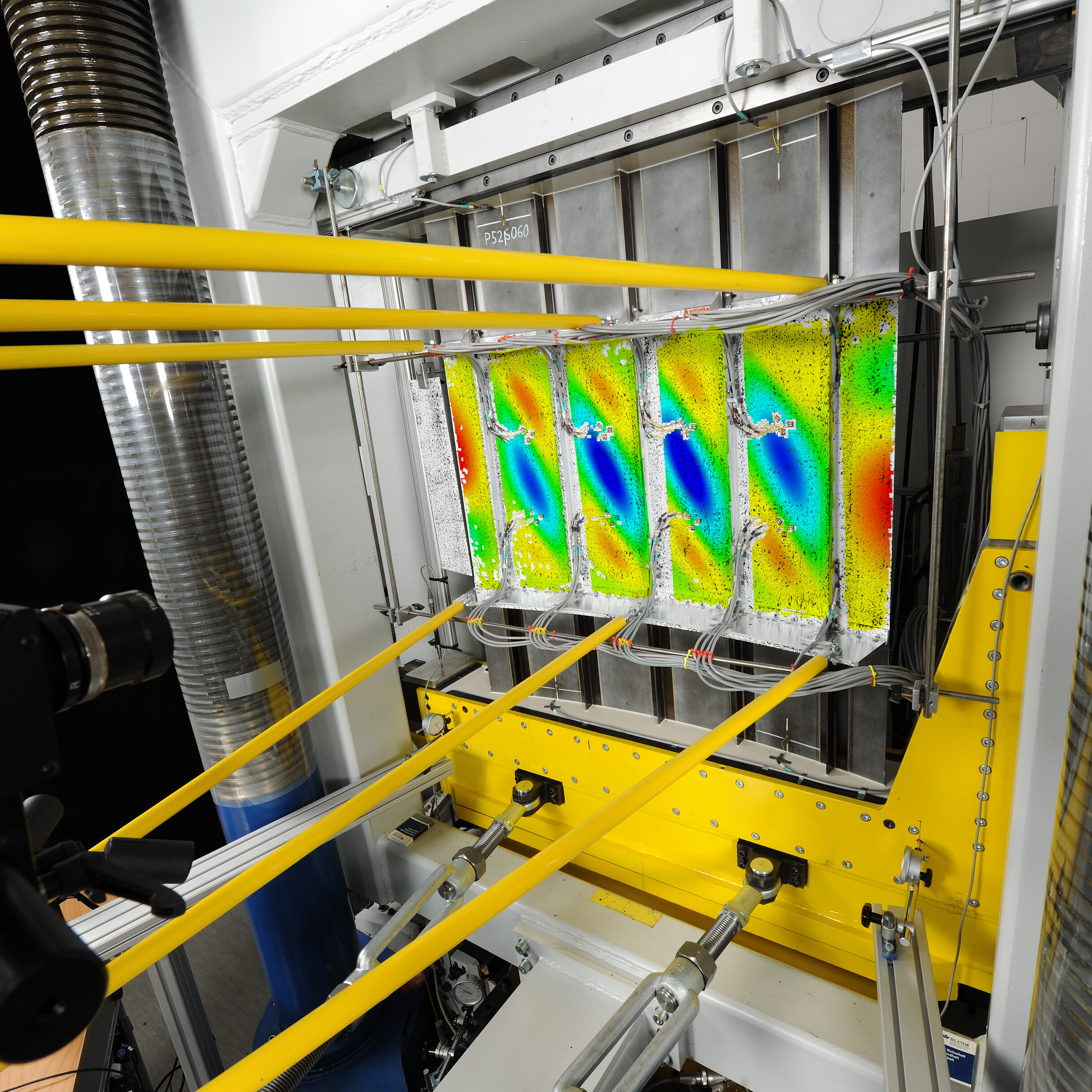

For experimental characterisation, we have an extensive laboratory infrastructure at our disposal, which is continuously being expanded. Accreditation according to DIN EN ISO 17025 and Nadcap underlines our claim to characterise materials at the highest quality level. The testing techniques are being further developed in the direction of process monitoring and Structural Health Monitoring (SHM) of fibre composite structures.

Performance profile

- Improvement and development of new injection resins

- Nanotechnology in fibre composites

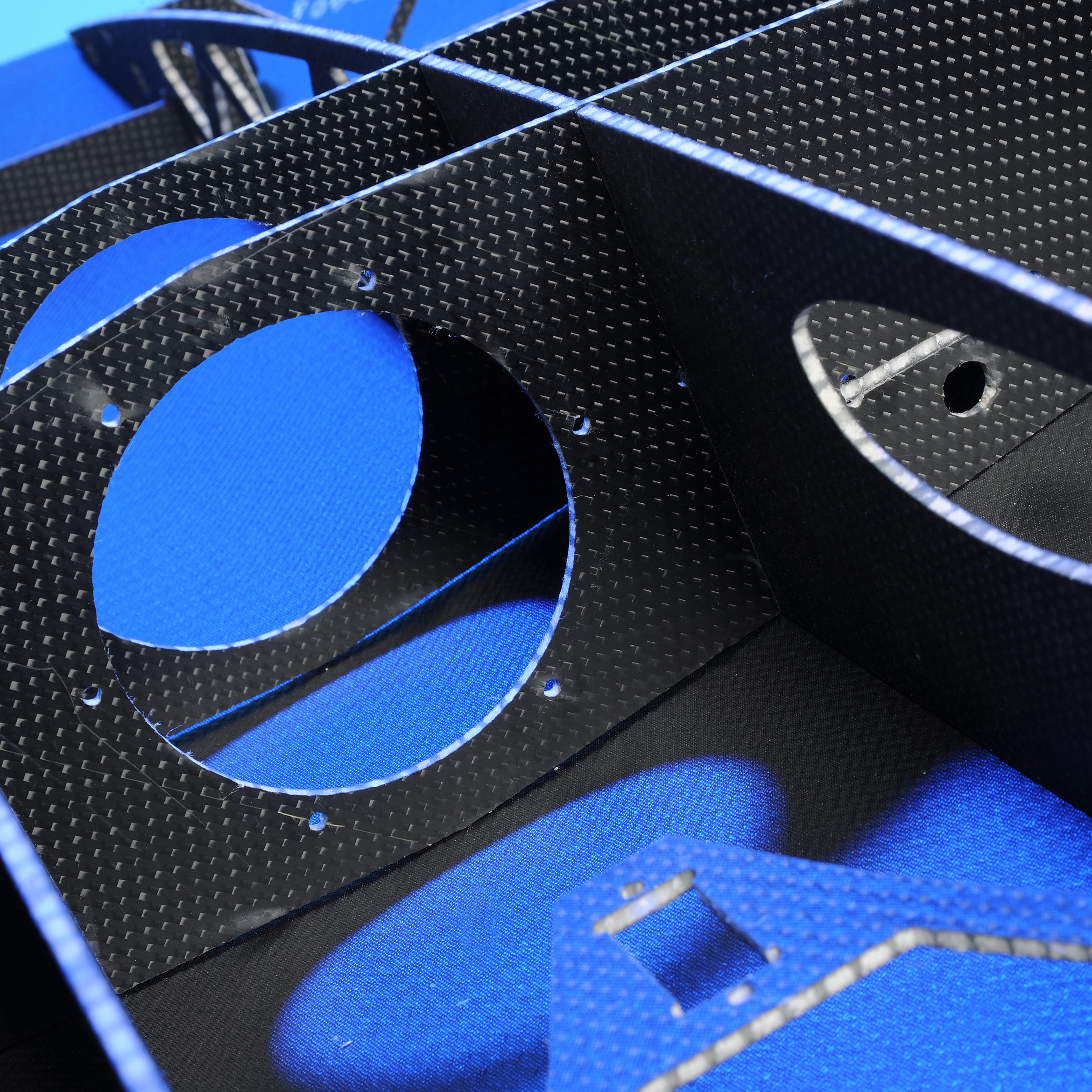

- Investigation of textile semi-finished products

- Composites from natural and recycled fibres

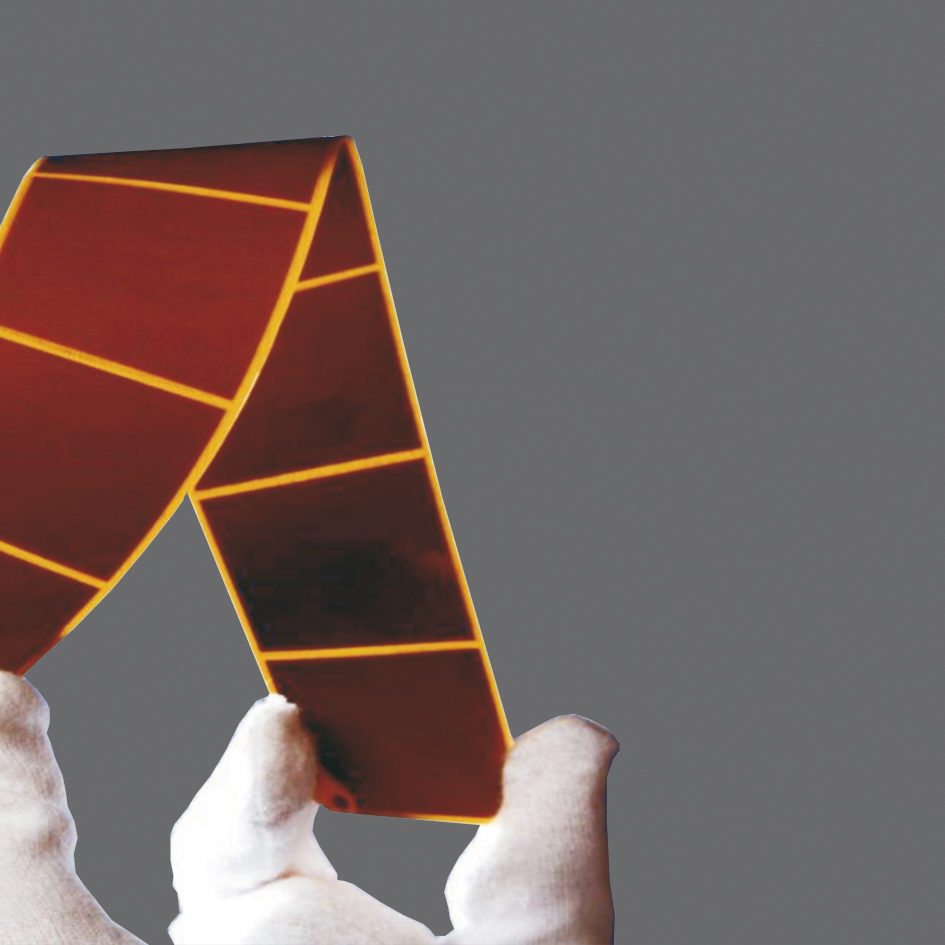

- Smart Materials

- Piezocomposites

- Structural Health Monitoring (SHM)

- Non-destructive testing of materials (NDT)

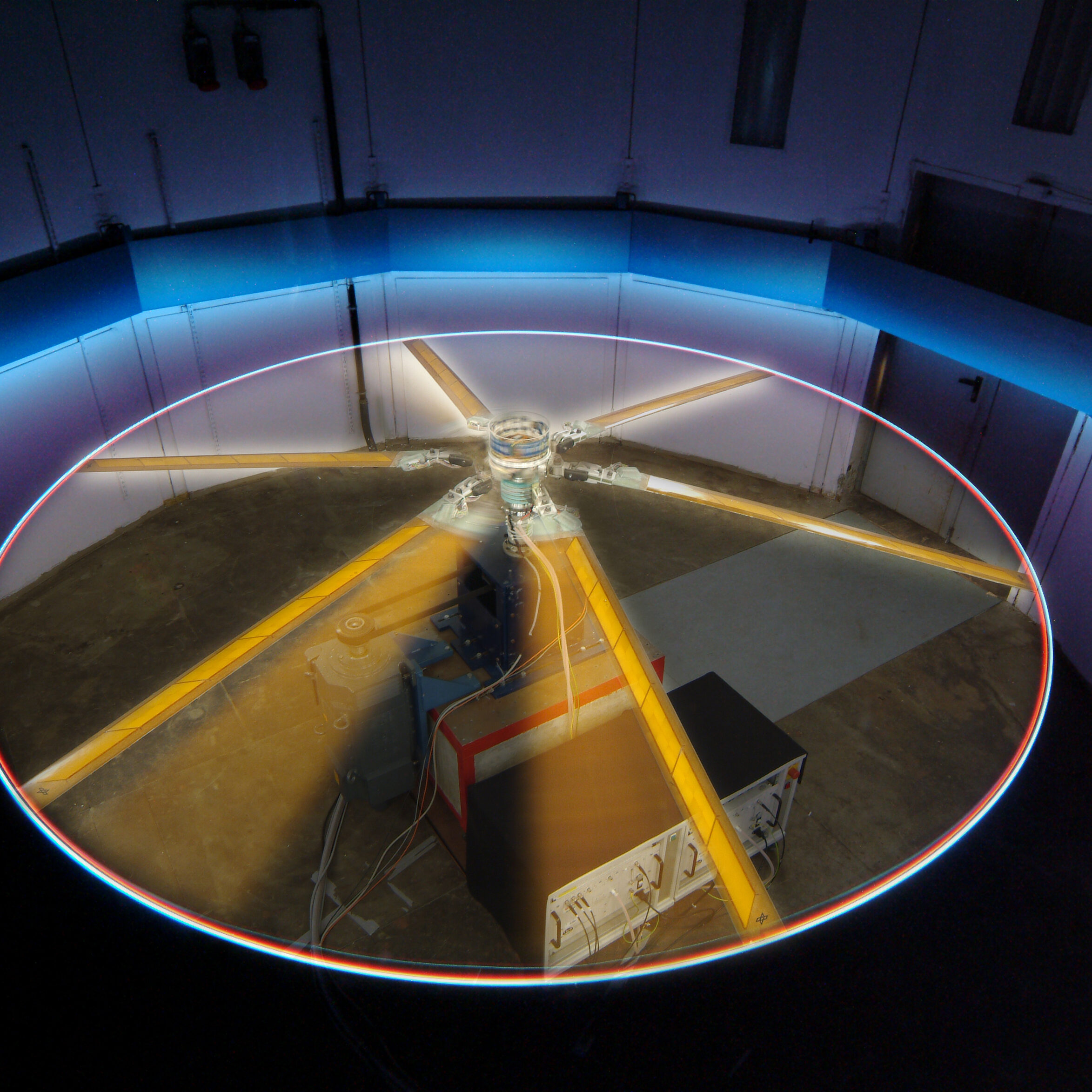

- Static and dynamic testing of materials and structures

- Thermal analysis and microscopy

- Life Cycle Assessment (LCA)

- Compounding and extrusion of thermoplastic materials for generative manufacturing processes