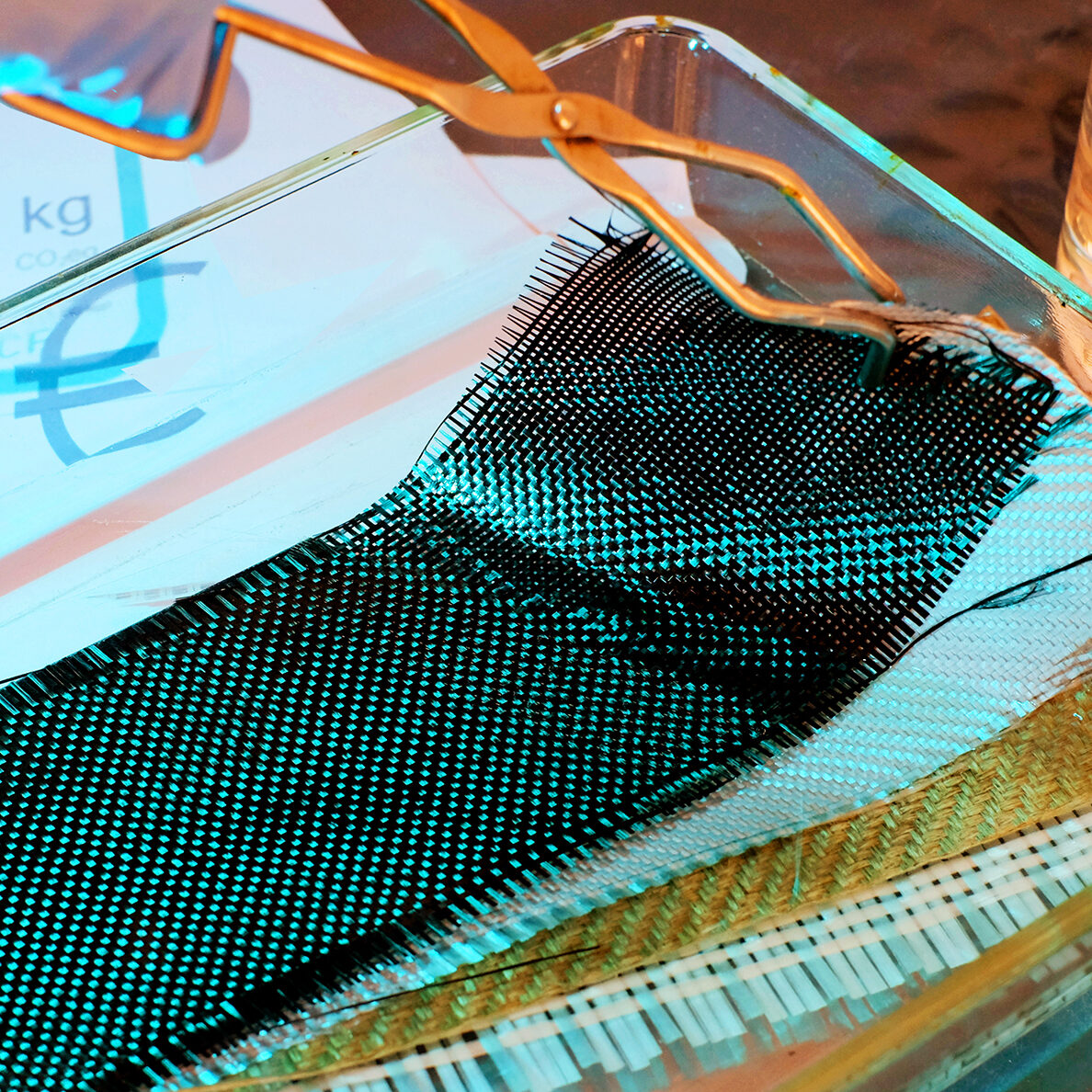

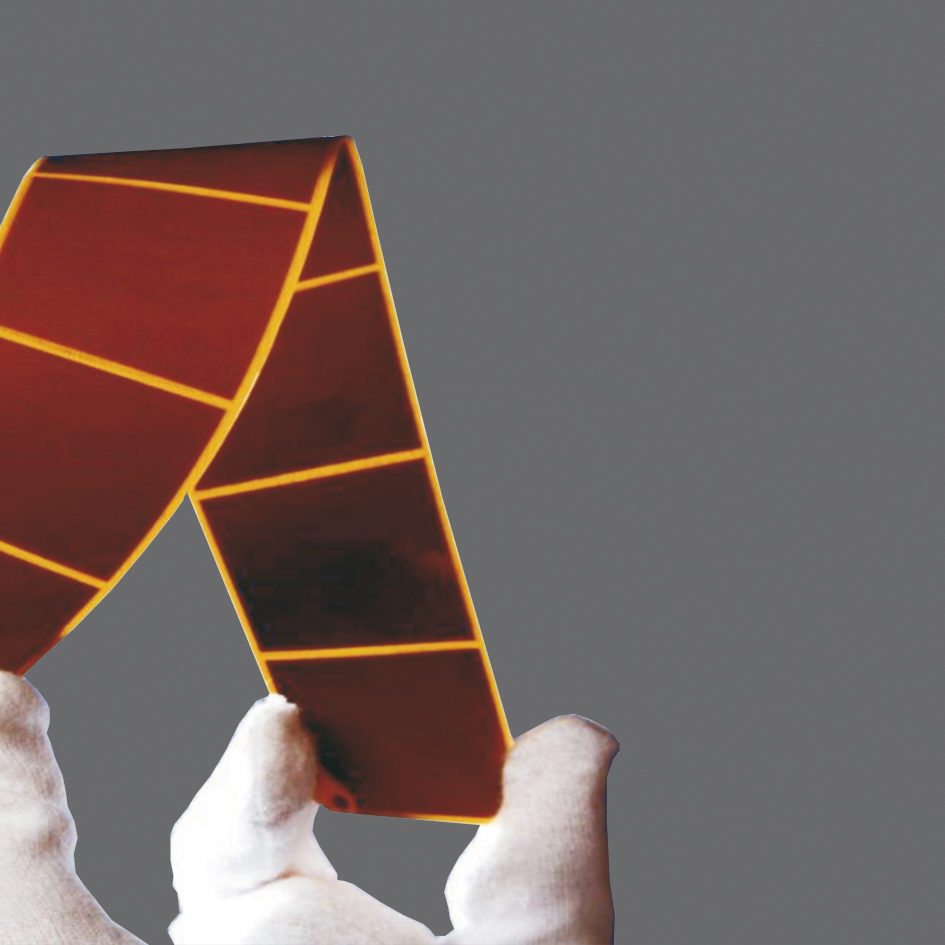

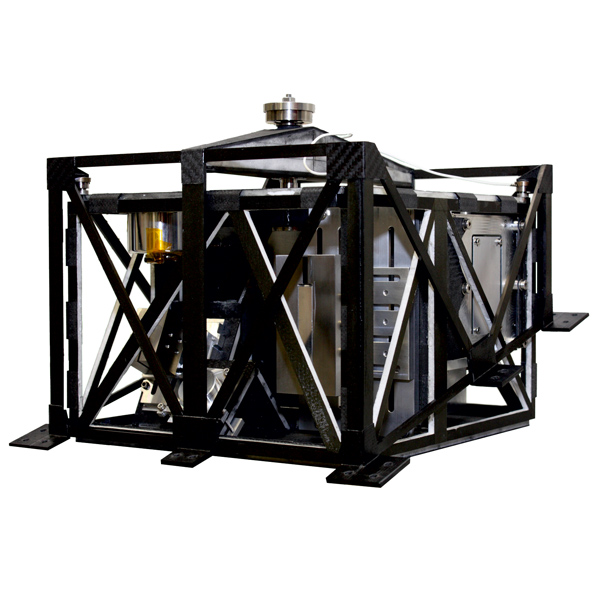

The business area “Fuselage” is dedicated to future fuselage concepts. Lightweight materials, e. g. CFRP and multi-material combinations are used and investigated to cover the main objectives:

weight and cost reduction. At the same time, more robust stability, residual strength and impact tolerance requirements are met to cover the functionalities of cabin and systems.

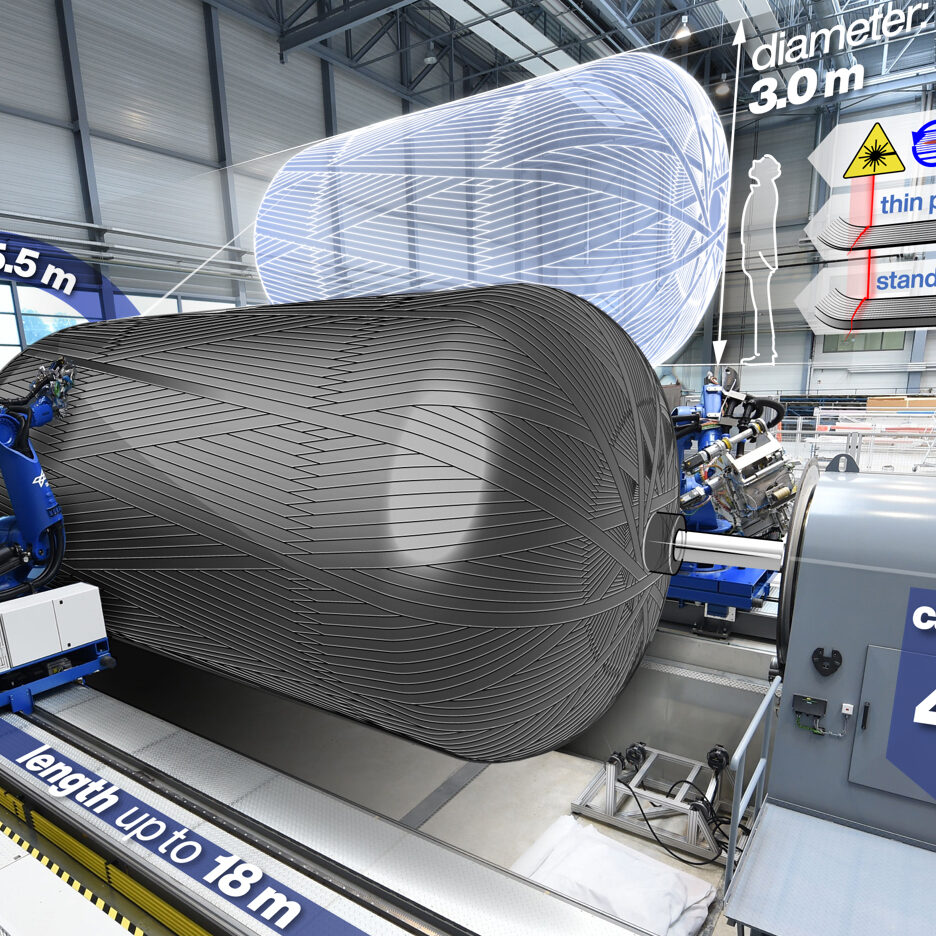

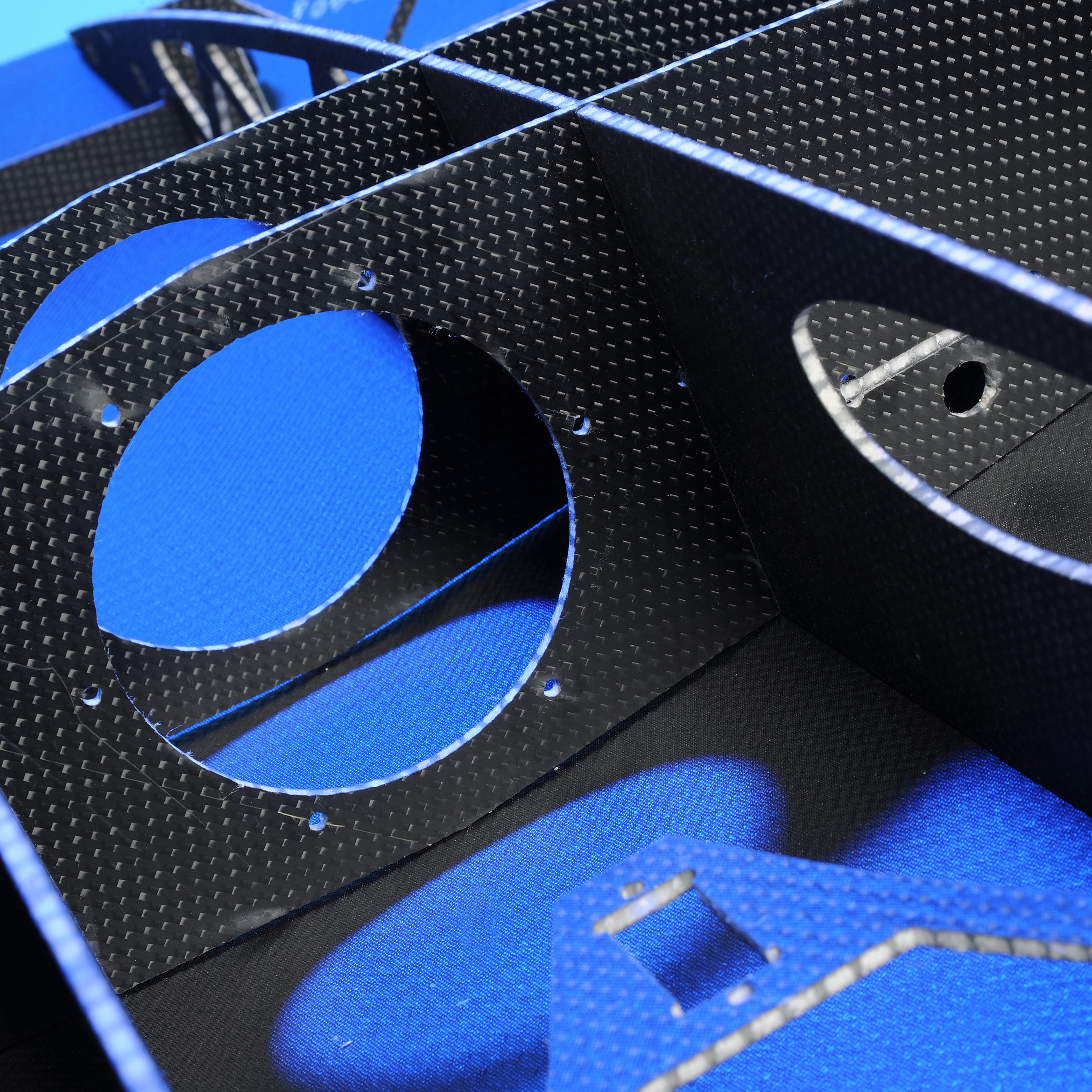

Improved design and analysis methods in conjunction with respective validation tests as well as commercially efficient production and assembly processes will directly be integrated into innovative and future-oriented fuselage architectures. For that, full-scale demonstration is a key enabler to cover large structural cutouts, e.g. passenger and cargo doors, load-carrying cabin elements as well as bonded and/or welded joining technologies. From an industrial point of view, the focus of research activities lies on large structural components, stiffening elements and secondary structural components of the cabin to finally achieve a safer and lightweight aircraft with integrated functions.