The UpLift project is developing and testing innovative hydrogen tanks for future short-haul aircraft. The focus here is on weight-saving composite materials, high-performance insulation systems and proof of safety and leak-tightness under real-life conditions. UpLift thus provides aircraft manufacturers, suppliers and decision-makers with a crucial basis for driving forward the climate neutrality of air transport by 2050.

Hydrogen tanks for short-haul aircraft – a step towards climate-neutral air transport

Within the framework of the BMWK sponsored UpLift project a test infrastructure for cryogenic hydrogen tanks is being set up on an application-oriented scale. The research activities based on this will then make a significant contribution to the ambitious goal of achieving climate neutrality in air transport by 2050.

The size of the tank structures investigated is based on future short-haul aircraft, as this is where the potential of hydrogen as a climate-neutral energy source can be introduced with an acceptable level of risk.

Short-haul flights are a very energy-cost-sensitive segment, as they compete with ground-based transport options. However, due to the steady expansion of the hydrogen sector, it is foreseeable that the price of sustainably produced hydrogen will fall considerably by 2050, making hydrogen more competitive than synthetic aviation fuel, for example.

Hydrogen can therefore be a decisive measure to reduce the negative impact of commercial air traffic on the climate, which according to current forecasts will more than double by 2050.

The technical solution at a glance

Storing hydrogen in a liquid state at extremely low temperatures down to -253°C is an essential prerequisite for future hydrogen-powered aircraft. The UpLift research project is therefore focussing on this topic in detail.

As the voluminous hydrogen tanks are likely to be installed in the rear part of the fuselage, minimising the structural weight is very important.

As the voluminous hydrogen tanks are likely to be installed in the rear part of the fuselage, minimising the structural weight is very important.

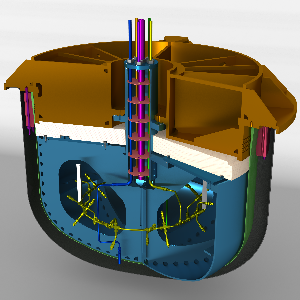

The test approach is based on a pressure-resistant cooling unit and a clamped inner cryogenic tank cap made of fibre-reinforced plastic. An outer tank cap made of fibre-reinforced plastic is added to create a representative volume between the tank structures so that suitable insulation strategies, in particular vacuum insulation, can be tested and evaluated.

The safety of a future hydrogen tank made of fibre-reinforced plastic has top priority, which means that gas tightness and structural integrity must be proven beyond doubt. The only way to achieve this is to test representative prototypes under realistic structural and thermal boundary conditions.

In addition, the production of the prototypes must be very close to the later production in order to find and eliminate possible weak points. Creating and maintaining an excellent vacuum is key to the effectiveness of the tank insulation, which in turn determines the amount of unwanted hydrogen boil-off.

Microcracks in the laminate, outgassing and gas diffusion must be reduced to a minimum in order to fulfil this requirement.

When a sufficient insulation level is reached, an innovative cooling system based on nitrogen vaporisation is activated to set the required temperature conditions. Minus 180° C is the upper temperature limit that can occur during operation, which means that this is also the relevant temperature for hydrogen permeation and leakage tests.

Another unique feature of the test system is the drastic reduction in tracer gas, as only the small gap between the cooling unit and the inner container is filled with either forming gas, helium or hydrogen. This reduces the testing costs in the case of helium and the risk of fire or even explosion when using hydrogen as the test gas.

The achievable structural performance of the tank is analysed and evaluated by checking the strain distribution in the relevant pressure range of 1 to 10 bar.

The hydrogen gas tightness of the inner tank and the effectiveness of the outer tank structure are assessed by checking the vacuum quality during pressurisation and by continuously monitoring the vacuum condition under operating conditions.

What remains – what is to come

Hydrogen-powered short-haul aircraft may enter service from 2040, which means that fundamental design decisions will have to be made within the next few years. This means that the Project UpLift in a perfect position to utilise the results for upcoming design decisions.

Looking ahead to 2050, the experience gained with hydrogen-powered short-haul aircraft and, in particular, the handling at the airport could well form the basis for even larger hydrogen aircraft and longer ranges.