In battery electric vehicles and in the first small electric aeroplanes, energy is stored in conventional batteries, which require installation space and significantly increase the mass of the vehicle. Concepts with structurally integrated energy storage systems, on the other hand, offer a way of compensating for these disadvantages. By combining energy storage and load-bearing structure into a single component, the mass and required volume can be reduced. This is achieved, for example, by eliminating the separate housing of the energy storage unit or by the energy storage unit itself transmitting mechanical loads and thus becoming a structure itself. As part of the SE2A Cluster of Excellence, the load-bearing integration of batteries in aircraft structures is being investigated in more detail. However, the cyclic loading of the structurally integrated batteries poses a major challenge. It is still unclear what influence dynamic forces have on the service life and properties of the batteries. Only by answering this key question will it be possible to fully assess the real potential of this energy storage concept.

What happens to batteries under cyclical load?

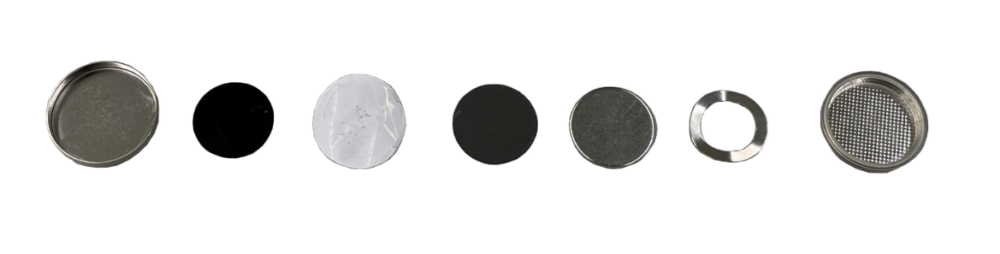

In order to analyse the influence of cyclic mechanical loads, the battery components, such as anodes and cathodes, are considered first. These electrodes consist of a collector coated with an active material. In the case of the anode, this is a thin copper foil coated with graphite. For the tests, the electrodes are dynamically loaded in tension until they fail. A small, intact part of this foil is then used to produce a battery in the form of a button cell. This makes it possible to evaluate the effect of the mechanical load on the performance of the battery. Both reference button cells consisting only of unstressed material and button cells in which either the anode or the cathode has been subjected to cyclic tensile stress are produced. The button cells are then electrochemically characterised using a potentiostat. This involves charging and discharging the cells several times and measuring the impedance. This provides a better understanding of how cyclical, mechanical loads affect the electrochemical properties of the electrodes.

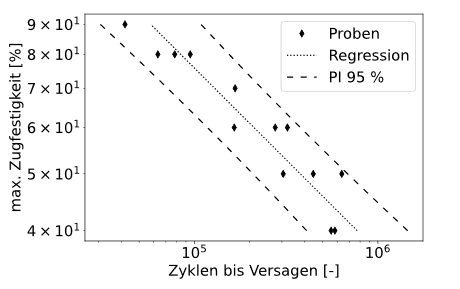

Winding the film onto rollers ensures an even load on the sample

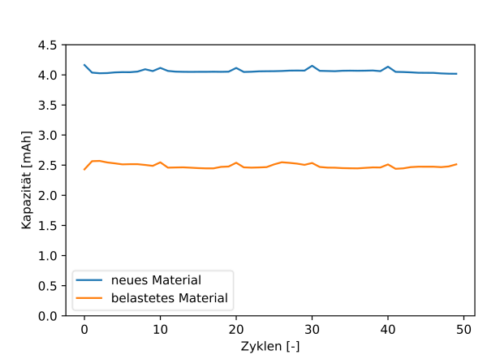

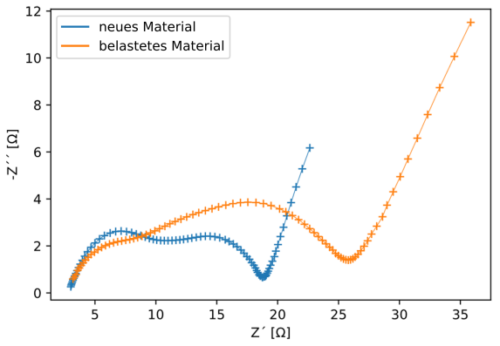

Discharge capacity and impedance spectrum of a reference button cell and a button cell with anode material tested at 70 % of the static tensile strength and failed after approx. 167000 cycles

Initial findings from the mechanical and electrochemical tests

When carrying out the tests, it became apparent that the clamping of the electrode foil is of crucial importance in generating reproducible results. In several optimisation steps, a clamping system was developed in which the ends of the electrode foil are wound onto metallic rolls. As a result, the stress in the foil builds up evenly, so that no critical stress concentrations occur. The experimentally determined Wöhler curve shows that the range between the two prediction limits is relatively wide, which indicates an increased scattering of the tests. All the tests carried out are within the prediction limits, although some of them are far away from the regression line. The increased scatter is probably due to the small number of samples (13 samples) and variations in the manual sample preparation. Initial tests with reference button cells and button cells with cyclically mechanically loaded anode foil indicate a significant influence of the dynamic loads on the electrochemical properties of the cells. This is demonstrated by the clear differences between the two cells in terms of discharge capacities and impedance spectra. Further investigations will help to better understand the underlying mechanisms and to transfer the findings from the mechanical investigations of the individual battery components to a complete battery cell. The overarching goal is to derive optimisation strategies that can be used to increase the mechanical robustness of the cells as a basis for successful structural integration.