SCOPRA (Sonic COmposite PRocess Analysis) is an ultrasound-based measurement system for monitoring the manufacturing processes of fiber reinforced composites, developed at the DLR Institute for Lightweight Systems. It enables comprehensive tracking of critical process steps, including impregnating dry fibers with resin and the resin cure. Using ultrasound eliminates the need for direct contact with the component, thereby avoiding sensor marks or vacuum leakage. The self-developed system features adapted yet simple sensors that support a high sensor count and easy integration. . Additionally, modular measurement hardware and software, along with multiple analysis methods and calibration data, allow the extraction of useful information from the sound signals..

The Challenge of Manufacturing Composite Structures

Finding suitable parameters for a robust manufacturing process for fiber composite structures requires extensive experience and often numerous trials. This is especially true for liquid composite molding (LCM) processes, where the challenge is guiding the resin to prevent unwanted entrapments of gas. A common occurrence is that resin flows faster around the component at unavoidable gaps between fibers and the mold than through the component, spreading from the edges toward the center. The point where the so-called flow-fronts meet can vary significantly from process to process due to variations in gap size and other deviations, such as preforming or resin flow behavior. These inclusions may remain as porosity or larger dry spots within the component, reducing mechanical properties or even causing scrap. Resin curing can also be affected by process deviations, such as uneven temperature distribution, mixing errors, resin aging, or moisture absorption. Typically, this is mitigated by extended curing times, at the cost of longer processing cycles.

Sensors Bring Light to the Dark

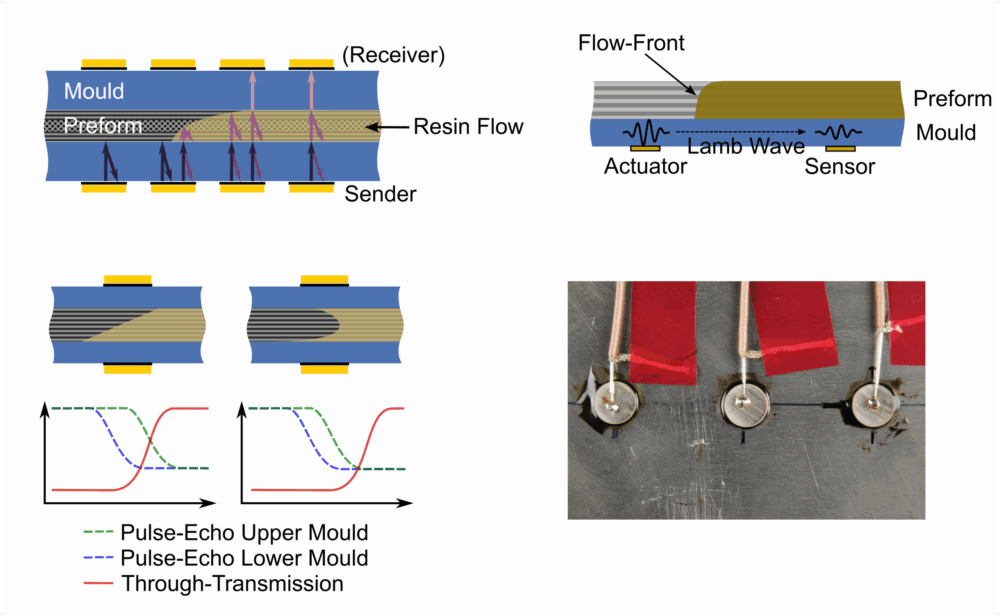

Depending on the process and complexity, resin flow cannot always be observed, for example, in closed molds or on the bottom side of thick components. Here, sensors can visualize hidden flow-fronts, providing critical insights into concealed processes. Unlike commonly used dielectric or pressure sensors, ultrasound sensors do not require direct contact with the component but are mounted on the mold’s outer surface. From there, sound signals are transmitted through the mold wall to the component, interact with it, and are then detected. Depending on the measurement method, detection can occur on the opposite or same mold half.

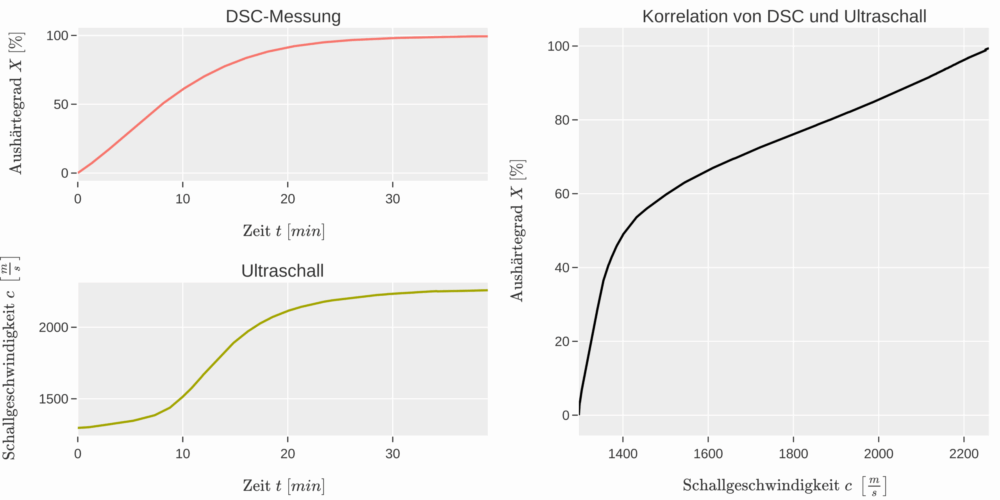

For resin flow detection, the pulse-echo method can be employed, where the same transducer both emits and receives sound. The reflection signal at the interface between mold and component is analyzed to detect impregnation at the mold-component-interface. Not only the time of flow-front arrival but also flow-front speed can be determined from the duration of signal change. In the through-transmission method, acoustic signals are detected by a separate transducer on the opposite mold half, enabling monitoring of impregnation across the entire component thickness. Using pulse-echo signals from both sides alongside the through-transmission signal allows differentiation between a “wedge-shaped” or “U-shaped” flow-front profile in the thickness direction. For cure degree determination, speed of sound is measured via through-transmission. It is closely linked to the material’s mechanical properties and can be correlated to the current cure degree through calibration measurements. Additionally, the gel point and vitrification point can be identified.

Beyond established pulse-echo and through-transmission methods based on pressure waves, guided waves – particularly Lamb waves – can also be used for process monitoring. Here, a transducer on one side of the mold half generates Lamb waves, detected by a second transducer at another location. Interaction between the waves and the component – currently being impregnated or cured – causes signal changes, from which the flow front position between transducers and degree of cure can be determined. This method offers particular value for monitoring cure degree, as it allows sensor integration on a single mold half without requiring a transducer on the opposite mold. Furthermore, transducers can also be permanently integrated directly onto the component to generate Lamb waves. This enables sensors not only for manufacturing monitoring but also for damage monitoring (Structural Health Monitoring) during the component’s operational life.

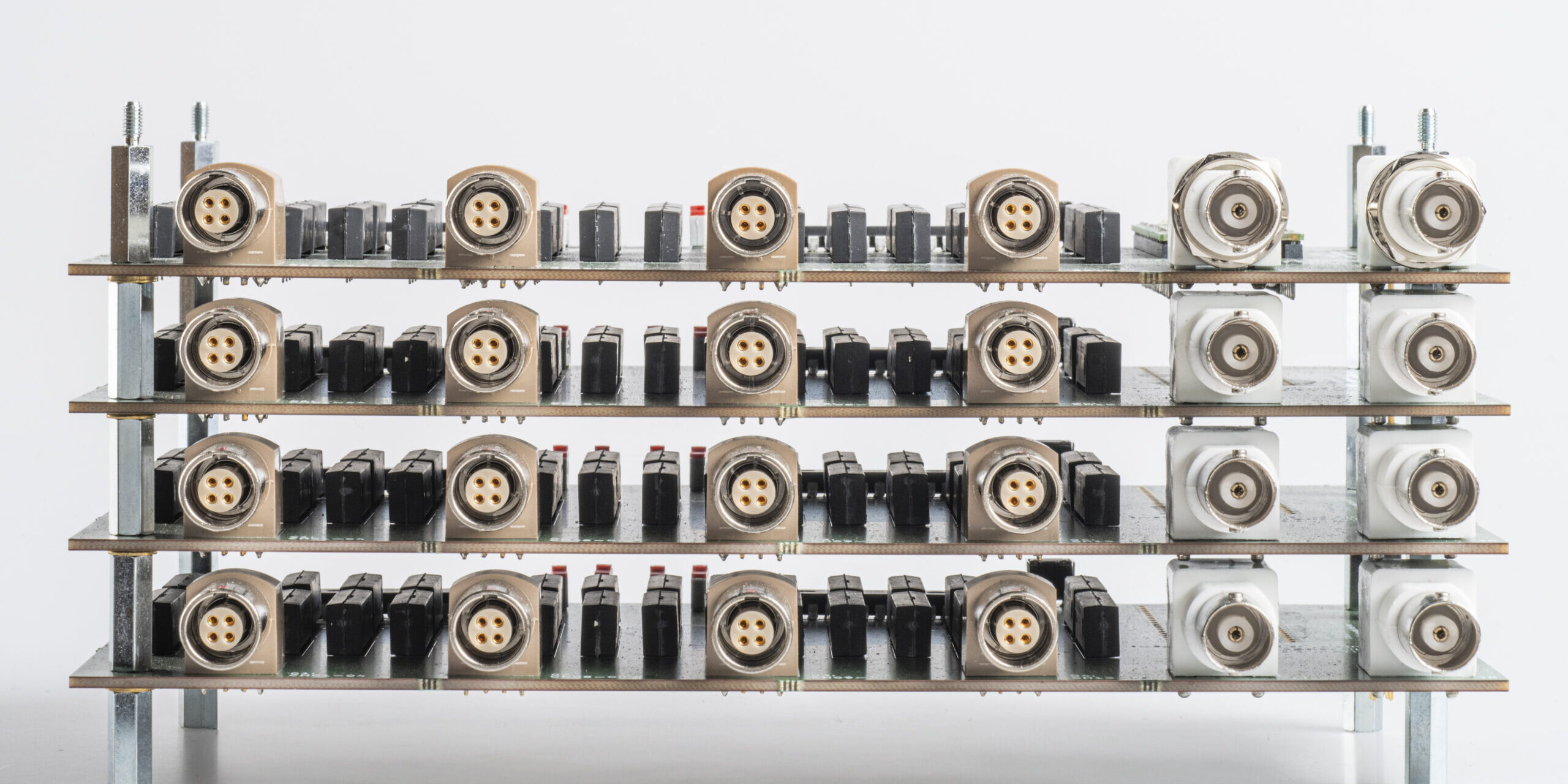

In the designing process of the measurement system, the focus was on in-house development and modularity. Software is developed in-house, enabling seamless integration of new algorithms and output formats, such as automated real-time provision of processed data. Similarly, the measurement hardware – sensors and multiplexers – is in-house developed, supporting large sensor counts and quick adaptation to new applications.

Outlook

Ultrasound enables simultaneous monitoring of resin impregnation and curing during the manufacturing of fiber composite structures. The developed system significantly accelerates the development of new processes and opens the possibility of sensor-guided manufacturing. Thanks to its modular and flexible in-house developed measurement system, a large number of sensors can be deployed, and the system can be easily adapted to new measurement tasks.