Production in Clear View: Ultrasound Uncovers Every Detail

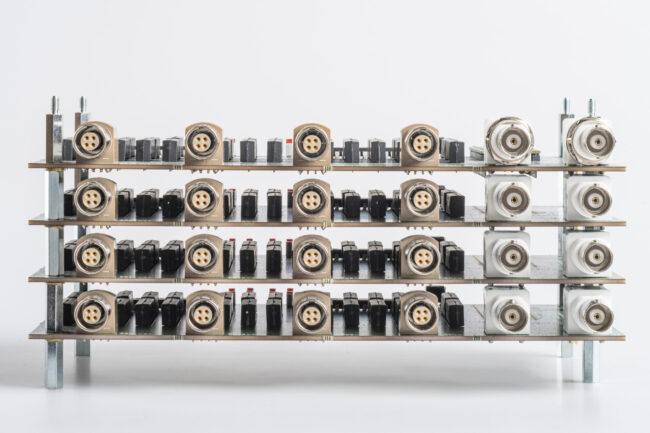

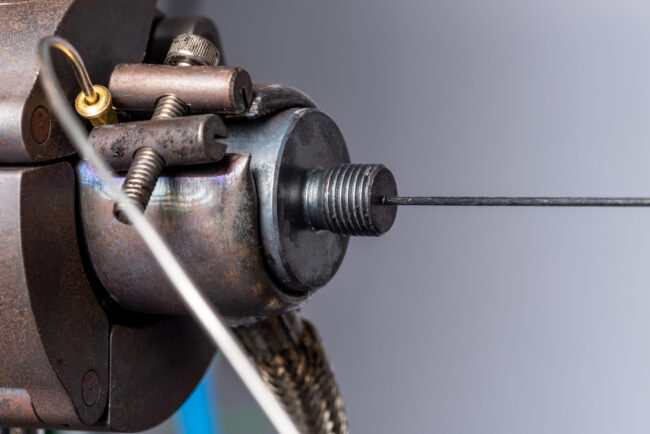

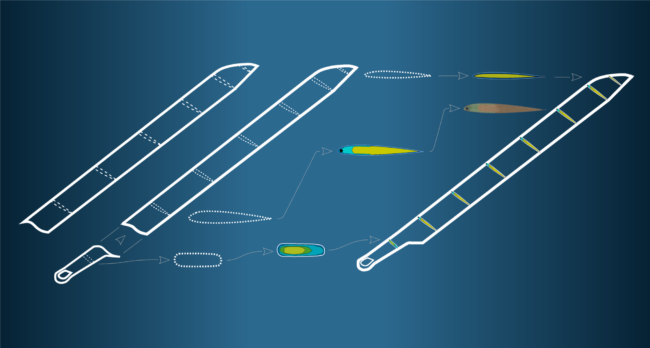

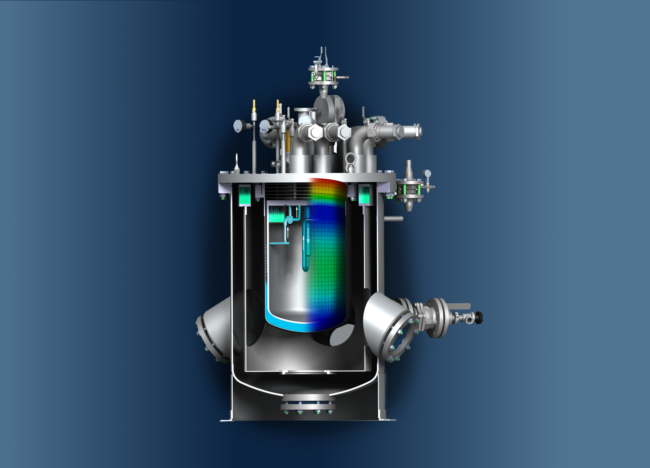

SCOPRA (Sonic COmposite PRocess Analysis) is an ultrasound-based measurement system for monitoring the manufacturing processes of fiber reinforced composites, developed at the DLR Institute for Lightweight Systems. It enables comprehensive tracking of critical process steps, including impregnating dry fibers with resin and the resin cure. Using ultrasound eliminates the need for direct contact with the…