The global climate targets require, among other things, a massive reduction in greenhouse gas emissions, including in aviation. Hydrogen as an alternative energy source for aircraft is a promising solution as, unlike jet-fuel, it causes hardly any direct climate-damaging emissions. One of the biggest challenges is the storage of liquid hydrogen (LH2) at extremely low temperatures. Efficient and safe LH2 storage systems are crucial and lightweight construction with carbon fibre reinforced plastics (CFRP) plays an important role.

Challenges of the CFRP tank

Current LH2 aircraft tank concepts are based on the proven principle of the thermos flask: a vacuum between two tank walls with special insulation (e.g. using a multi-layer) thermally isolates the surroundings and minimises heat loss. This ensures high storage efficiency.

In addition, leaks in the tank must be prevented at all costs. The large temperature difference between the production of the tank structure in the autoclave at up to 180 °C and operation at -253 °C causes considerable thermal residual stresses in the fibre composite. This can result in microcracks. Combined thermo-mechanical stresses can even cause micro-crack networks with leakage paths through the tank wall. If liquid hydrogen escapes, the high rate of expansion during the transition to the gas phase can lead to a considerable increase in pressure in the insulation and even to structural failure.

There are three main concepts for making hydrogen tanks leak-proof:

- Liner concept: A metal or plastic barrier is used here. However, this method does not solve the actual problem of microcracks. Furthermore, a liner also increases the weight of the tank and the complexity of production and assembly.

- Thin-ply concept: This concept uses particularly thin laminate layers (thin-plies), which are intended to prevent cracking due to their increased crack resistance.

- Cryo-optimised materials: This is the most promising concept, as it aims to prevent the onset micro-cracks using specially developed materials. This eliminates the need for additional barrier layers, which saves weight and production costs.

The combination of thermal and mechanical loads during operation represents a major challenge for tank development – especially when it comes to precisely simulating these conditions on a test bench, particularly as these loads act in different directions and occur both cyclically and constantly. Classic universal testing machines reach their limits here, which is why new test methods are required.

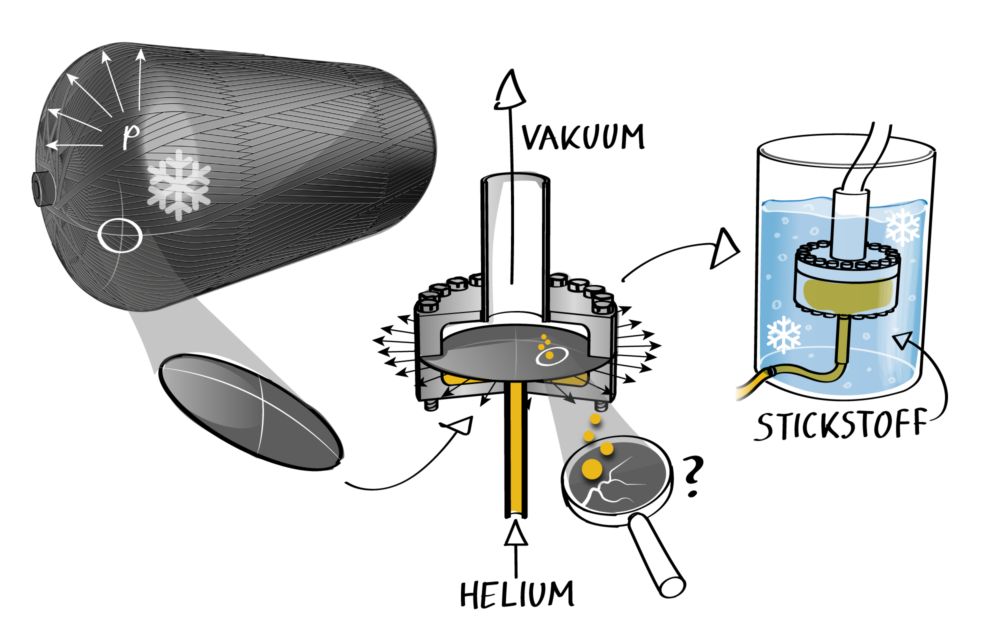

The bulge test rig

Detecting microcracks and microcrack networks in the tank structure is extremely difficult. Using traditional methods such as microscopy or CT analysis, it is often a matter of luck to find the right spot. The bulge test rig offers a decisive advantage here. It makes it possible to reliably test the tightness of CFRP test specimens. The test specimen is clamped in a clamping device and cooled to cryogenic temperatures. Helium is then fed into one chamber at up to 20 bar, while a vacuum (1E-02 mbar) prevails in the other chamber. The resulting pressure difference causes the test specimen to deform in a similar way to a real tank. A mass spectrometer measures the helium leakage flow as soon as the test specimen starts to leak. This allows the limits of the material to be precisely determined. The highlight is the use of helium as a substitute gas for gaseous hydrogen for leak detection and liquid nitrogen (LN2) as a substitute medium for LH2 for cooling. Similar molecular and atomic sizes and comparable boiling points (-253 °C vs. -196 °C) ensure that the results can be transferred with significantly less effort. With this simplified procedure, important findings can be obtained quickly, e.g. with regard to the evaluation of the concepts described above for a leak-free LH2 tank. The solutions developed in this way must then finally prove their suitability under LH2 conditions.

Future prospects

The development of LH2 tanks made of CFRP raises many questions. The approach presented here helps to answer fundamental questions safely, cost-effectively and time-efficiently and to accelerate tank development. In addition to answering questions about the material, the bulge test bench can also be used to test feedthrough concepts for the tank.

Funded by the Federal Republic of Germany

Funding organisation: Federal Ministry for Economic Affairs and Climate Protection on the basis of a resolution of the German Bundestag.

The activities were funded as part of the LuFo VI-3 programme through the UpLift project.