The German government’s Climate Protection Plan 2050 also calls for radical CO2 savings in aircraft construction and operation. One way to achieve this is to switch from conventional to hydrogen-based propulsion systems, be it fuel cells with electric propellers or hydrogen-powered gas turbines. The integration of such drive systems and their components, such as hydrogen storage in particular, presents designers with completely new challenges. Liquid hydrogen tanks made of CFRP are currently being investigated at the Institute of Lightweight Structures as a promising lightweight construction solution. In co-operation with industrial partners, the focus is particularly on differential concepts. Like the aircraft fuselage, the CFRP tank is also being assembled from individual segments in current research projects.

Why structural bonding?

Anyone who has ever had to bond something has probably had the unfortunate experience that bonds can fail unexpectedly. This disappointment is usually due to the choice of an unsuitable adhesive system, inadequate surface pre-treatment of the bonded parts, insufficient understanding of the thermomechanical load condition or environmental influences such as humidity and temperatures. Due to the complexity of the design, dimensioning, process technology and quality assurance of bonded joints, traditional aircraft construction still relies on riveted joints, which are otherwise only found on old railway bridges from the 19th century. Even in the most modern CFRP fuselages, riveted joints are used in the primary structures for reasons of conservatism at the expense of lightweight construction potential. In the case of an aviation-suitable liquid hydrogen tank in thermoset CFRP construction, safety considerations and functional requirements for the structure in particular lead to the selection of bonding as the joining technology, in addition to the lightweight construction concept. These include, in particular, strict requirements with regard to tightness (permeation and leakage) and the joining of a wide variety of materials, such as GRP and CFRP with Aluminium and steel alloys, as well as the application of insulation materials. In addition to purely structural load-bearing capacity, adhesives also fulfil other safety-critical tasks, such as ensuring tightness, bridging different thermal expansions in the joining area, as well as the targeted use and reduction of thermal resistance in joints, depending on requirements. A wide range of functional requirements and joining partners requires a variety of special adhesives that can withstand the extreme temperature conditions of -253 °C. Despite the use of proven design philosophies such as ‘fail-safe’ and ‘damage tolerance’, bonding on hydrogen tanks remains safety-critical. The adhesives used must therefore be selected on the basis of comprehensive and reliable data. The CryoTAST test rig is used for this purpose.

What does CryoTAST actually stand for?

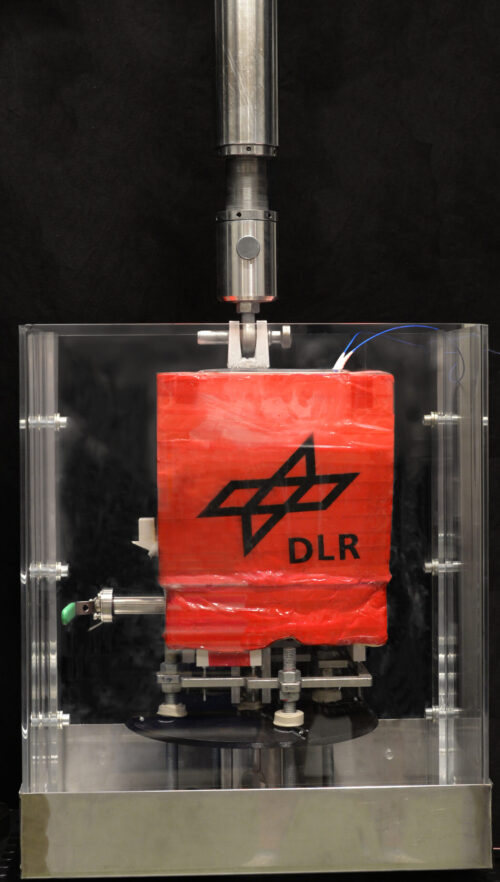

CryoTAST stands for Cryogenic Thick Adherent Shear Test and refers to a test rig developed at the institute for screening potentially suitable adhesives at -196°C. In accordance with ASTM D 5656, this test rig is used to test thickness, tensile and shear specimens. These are bonded aluminium test specimens. The test rig is used to determine the shear modulus, the shear strength and the characteristic stress-slip curve of an adhesive. This database is crucial for the safe design and dimensioning of bonded joints on liquid hydrogen tanks. The CryoTAST test rig is the first selection stage in a cascade of adhesive tests. In co-operation with partners from industry and research, the CryoTAST test rig is currently being used to evaluate the potential of special cryogenic adhesives in comparison with structural adhesives established in the aerospace industry. From an industry perspective, it is already foreseeable today that manufacturing tolerances of the segments will mean that uniform adhesive gaps, as in the laboratory, cannot be realised in practice. The CryoTAST test rig is used to experimentally determine the influence of varying adhesive layer thicknesses for individual adhesives. The characteristic values derived from this serve as input variables for FE simulations. Based on this simulation, permissible manufacturing tolerances are defined for the liquid hydrogen tank.

Why are bubbles problematic?

In order to achieve the test conditions of -196 °C, the CryoTAST test stand has a reservoir with 4 liters of liquid nitrogen. The test specimen is immersed in this nitrogen bath while a tensile force is applied. Under normal atmospheric conditions, liquid nitrogen boils at -196 °C. The turbulent conditions in the reservoir are therefore similar to those in a pot on a cooker in which tap water boils at 100 °C. At the same time, deformations in the range of a few micrometers are measured in the turbulent nitrogen bath using a capacitive extensometer attached to the test specimen. The recording of reproducible, interference-free strain signals under these extreme conditions and the understanding of transient heat flows and the associated temperature gradients in the test setup are the main challenges in the development of the test bench.

Funded by the Federal Republic of Germany

Funding organisation: Federal Ministry for Economic Affairs and Climate Protection on the basis of a resolution of the German Bundestag.

The activities were funded as part of the LuFo VI-3 programme through the UpLift project.