Improving damage tolerance: New methods for optimised aircraft design

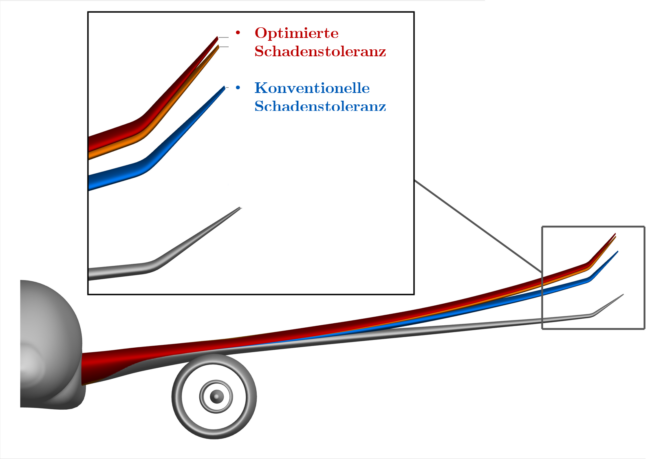

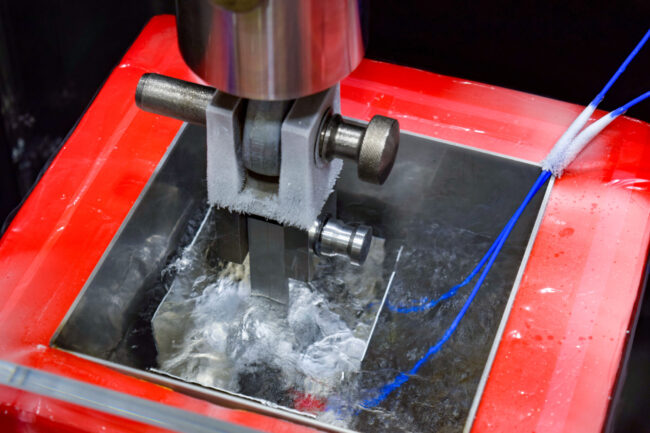

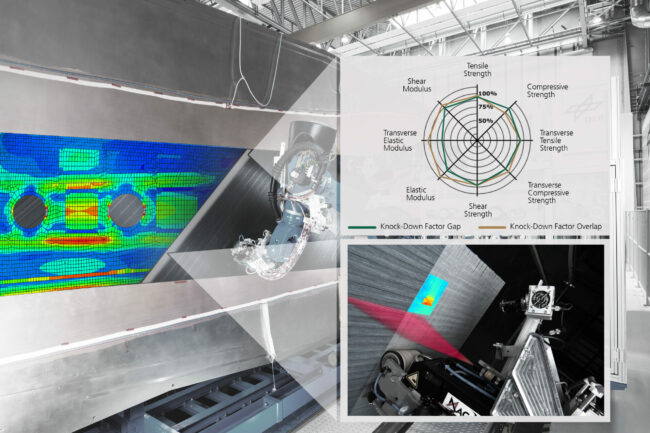

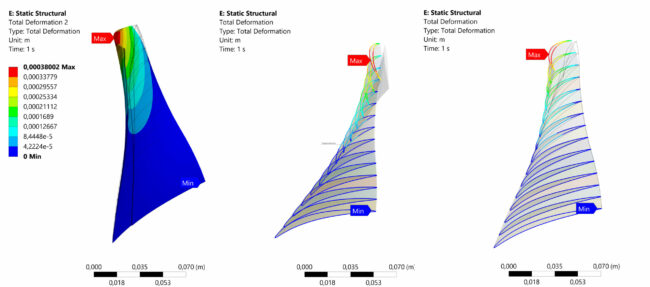

The safety and efficiency of aeroplanes depend to a large extent on the resilience of their structures. Damage cannot be prevented during the operational life of an aircraft. The best possible methods for damage assessment are therefore essential. In order to utilise the lightweight construction potential of CFRP as well as to ensure operational safety,…