The Composite Companion allows the simple integration of experimentally and numerically determined characteristic values through a well thought-out structuring of the data. It lays the foundation for efficient data analysis of material and process parameters of fibre composites. The Composite Companion allows different processes, scales and temporal resolutions to be taken into account. The realisation as SaaS (Software-as-a-Service) makes integration into a wide range of applications easier.

Goal: Optimisation of processes and understanding of materials via data

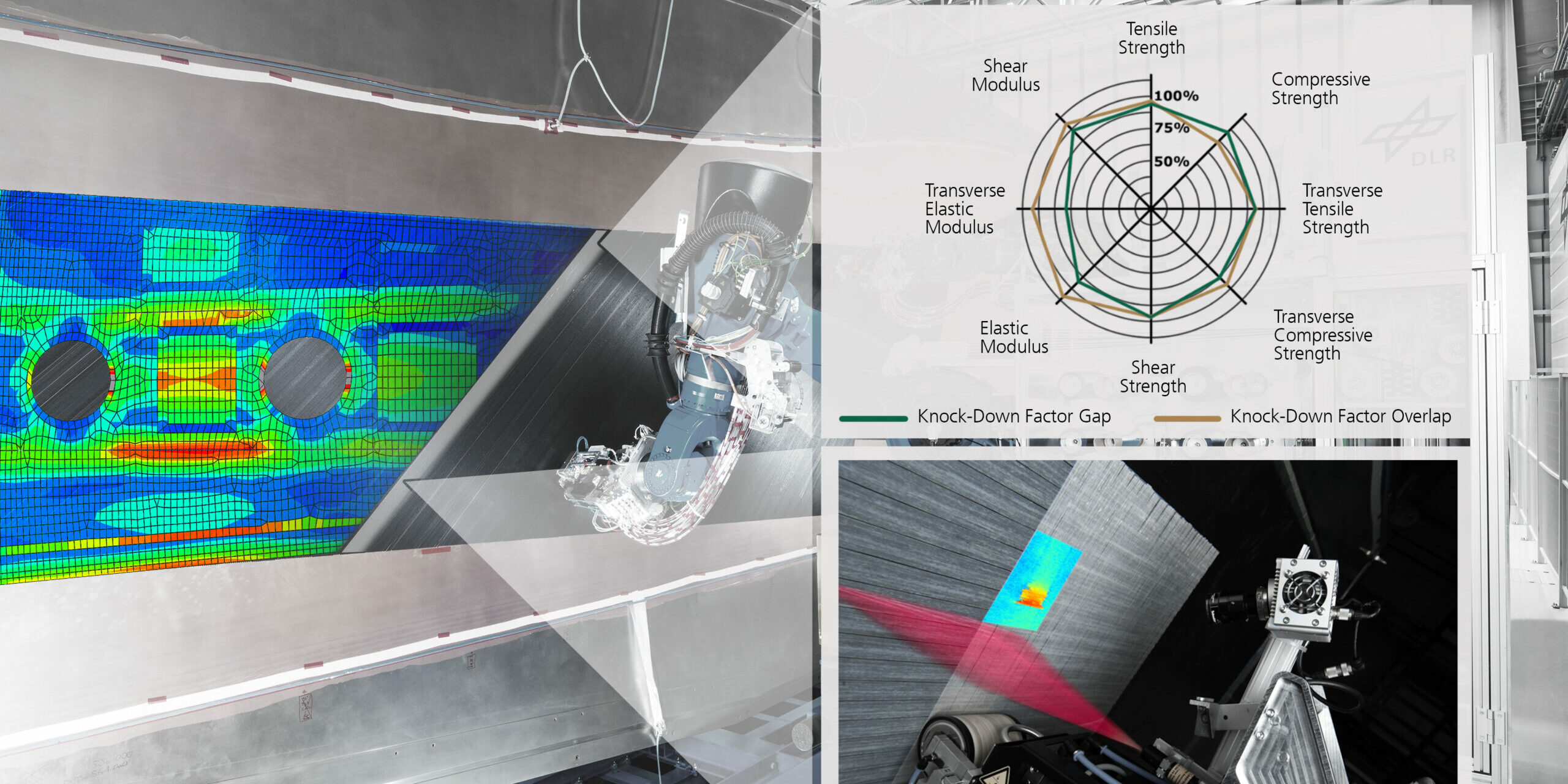

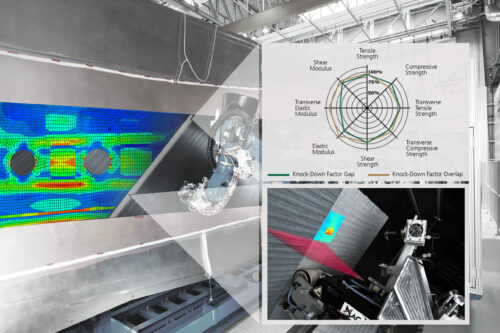

Sustainably manufactured structures and production processes are essential to ensure the protection of the environment. By increasing the service life or avoiding rejects, it is possible to reduce the amount of resources required in the production of lightweight structures made from fibre composites. In order to achieve these goals, it is important to have a good understanding of the manufacturing process used and the material properties. In lightweight fibre composite construction, the material properties of the resulting laminate are created during production and are therefore significantly influenced by the manufacturing process. An automated manufacturing process is shown as an example and the scattering of the characteristic values in the component due to the process and the varying fibre placement is shown schematically. If these characteristic value scatters or the resulting interactions are not known, this can lead to rejects. Measurements during the manufacturing process, as shown in the image, and the interpretation of the data can close this information gap.

Challenge: small amounts of data – different data formats, no standards – lots of variability.

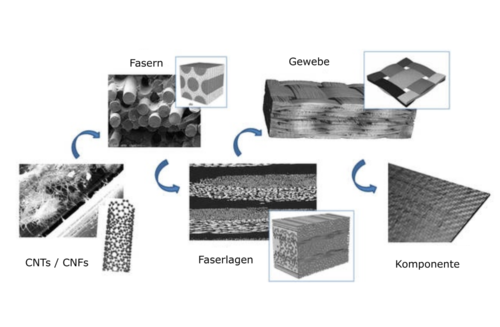

Nowadays, various methods such as data analytics, data science, machine learning, AI, etc. are available to extract information from data. It is a widespread assumption that the amount of data only needs to be large enough for a result to be found and that no prior knowledge is required for this. Successes in image recognition, translation algorithms or chess-playing computers are cited as evidence of this. However, although these areas are characterised by large amounts of data, they are also characterised by clearly defined rules. These conditions do not typically exist for fibre composite lightweight construction. The quantities tend to be small and there are no rules or rules that are difficult to formalise. There is often a lack of standards for data collection and storage and the variability in the data is high. To illustrate the complexity: There are different fibre composites (woven fabrics, unidirectional plies) and different scales (microscale, laminate, structure), each of which has specific characteristic values.

Solution approach: Composite Companion

Structured data helps with such a high degree of complexity. This involves pre-interpreting the data by structuring it appropriately. The subsequent analysis is carried out with already interpreted data and not with the pure raw data. As material and process parameters are already defined by models, the machine learning algorithms do not have to recognise them first. This reduces the amount of data required and makes the interpretation of the results simpler, comprehensible and verifiable. Structuring data in this way is not trivial and requires a great deal of experience. As part of the Institute’s digitisation strategy, such structuring was carried out for fibre composite materials. The advantage is obvious. The well thought-out structuring of the data allows the simple integration of experimentally and numerically determined characteristic values and makes them more comparable. The data structure is mapped in a database and attempts to address a wide range of applications. It takes into account different processes, scales and time resolutions. The software implementation enables simple connection to a wide range of software services, as shown in the illustration.

What is the advantage?

The developed data structure and the associated expert knowledge make it possible to analyse measurement data at different points in the life cycle, over longer periods of time or from different batches. This includes scattering, statistical analyses and other forms of data analysis that enable the identification of “weaknesses” in manufacturing processes. By structuring the data in advance, targeted process optimisations or improvements can be realised. This is because, in contrast to an unstructured approach, the pre-interpreted data used has a clear meaning. With the Composite Companion as a data model for the structured storage of pre-interpreted data, we are paving the way for such analyses and want to make data available to the general public in a professionally prepared form in the future.