Non-cutting metal replacement – continuous fibre-reinforced 3D printing filaments

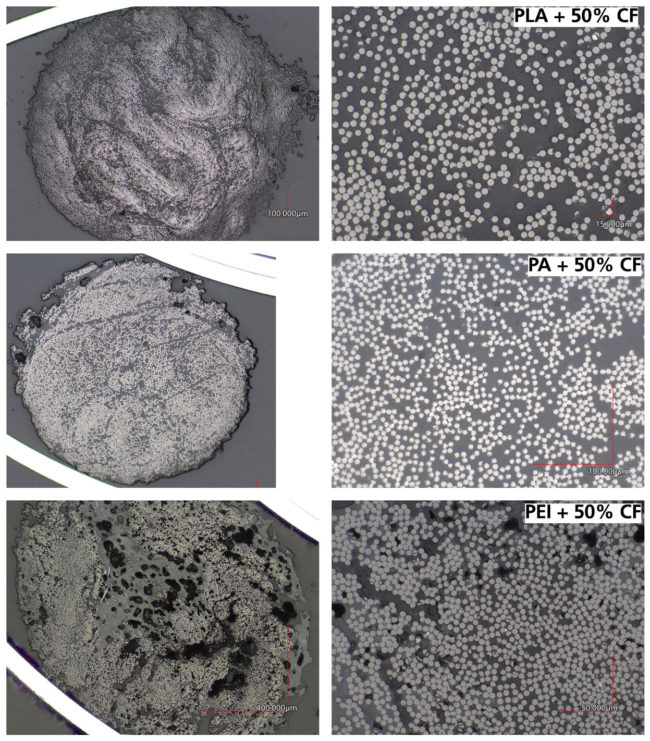

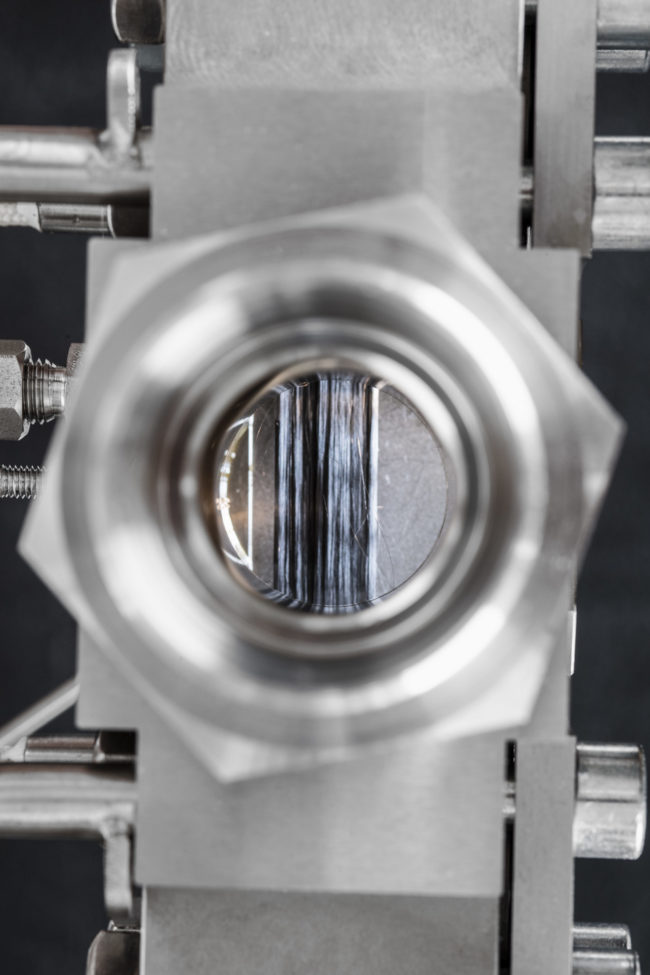

A newly developed impregnation technology enables cost-effective and flexible production of continuous fibre-reinforced thermoplastic 3D printing filaments. When combined with additive material extrusion processes, this makes it possible to implement lightweight yet highly resilient components made of thermoplastic fibre composites cost-effectively, even for new businesses and manufacturers of small production runs. Production of continuous fibre-reinforced…